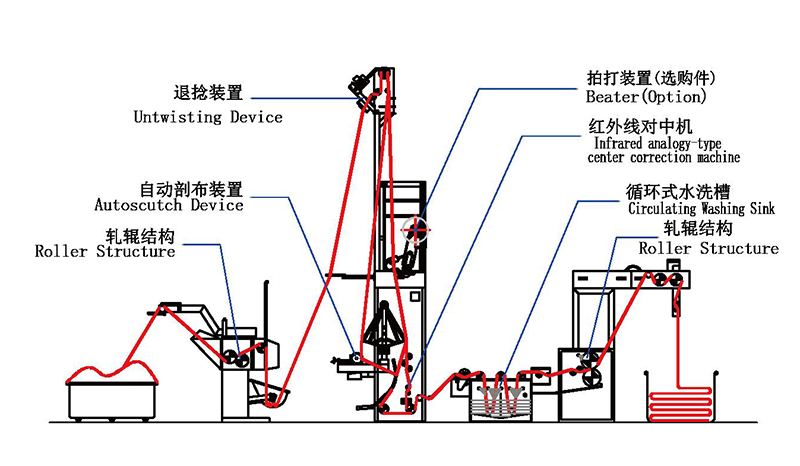

VS-E Untwisting, Scouring and Squeezing Machine

Short Description:

Application:

The machine is suitable for cutting, opening width, scouring and squeezing after cloth dyeing process. It replaces the traditional process of slitting and dewatering, reducing labor intensity, saving manpower, shortens the process time.

Technical Features:

1, Lift type untwisting: Untwisting effect is up to 100%, no need climbing up and down to feed cloth, dangerous accidents are avoid

2, There are two kinds of cloth cutting head: semi-automatic manual adjustment knob alignment and the magic eye automatic alignment, and the full-automatic alignment device can track cloth cutting threads automatically. Pulley structure is adopted for cutting head umbrella stand, flexible with small tension, to solve unstable gram weight caused by excessive tension

3, Conveyor device without tension can reach full shrinkage of cloth cover before entering into the padder, to make the gram weight more stable after finalizing the cloth cover

4, Exclusive frequency conversion control is adopted for cloth discharge, which can be adjusted to be open width cloth discharge or wave cloth discharge according to customer's requirements

5, The machine has 3 functions in one, direct squeezing can leave out dehydration, and it can conduct cloth cutting or twisting open width

6, High pressure roller is made of imported materials by advanced technology. Cloth cover moisture content after squeezing is lower than that of the industry average rollers.

7, The direct scutching squeezing after out of cylinder can reduce labor intensity, shorten the process time, improve work efficiency

Technical Parameters:

| Applicable fabrics | Open-width knit and tubular fabric |

| Working width | 2200mm, 2400mm |

| Maximum speed | 0-100 m/min |

| Motor power | 22KW |

| Power supply | 380V 50Hz |

| Dimension(L*W*H) | 10500*4200*6000mm |

Our professional team will give you the best suggestion as long as you tell us what kind of test you need to do andthe required specification.

At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15~20 working days after deposit receipt. If you are in urgent need, we can consider making special arrangement for you.

Yes, of course, we can not only offer standard machines, but also customized machines according to your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to arrange hotel and pick up you from airport.

Now our testing machines have been sold to more than 80 countries, like USA, Canada, Russia,UK, Italy, Germany, European ,India,Pakistan, Philippine, Singapore, Malaysia,Thailand , Vietnam, Korea,Saudi Arabia,Brazil…and so on.

Generally,our warranty is one years. Within the warranty period, we can offer technique support and part parts change, necessarily, our engineers may go to your place for better service.

Our machine is packed by standard export wooden box, it won’t be damaged. We’ve delivered many testing machines abroad by sea or by air without damage.

Inquiry – quotation – communication – order confirming – deposit payment – production – testing and debugging – balance payment-packing – delivery – customer receiving – after service.

The product is shipped with an operating instructions and video of English version.

With the continuous improvement of the functional requirements of textile finishing machines in various countries, the structures and functions of our fabric inspection machines, fabric slitting machines, and fabric folding machines are constantly being adjusted.