RH-D Loom Take-up Inspection Machine / Batcher Winder

Short Description:

Technical Features:

1, The machine can be completed with any type of weaving loom

2, The reliable and stable dual converter winding control mode is adopted

3, When loom is running, the batcher can be backward for inspecting the fabric

4, The constant tension control control is adopted

5, Equipped with pneumatic fabric doffing device

6, Equipped with incline fabric inspection frame

7, Precision decline gear transducer motor is adopted

8, Edge in line precision is ≦5

9, Suitable for winding any standard fabric

Technical Parameters:

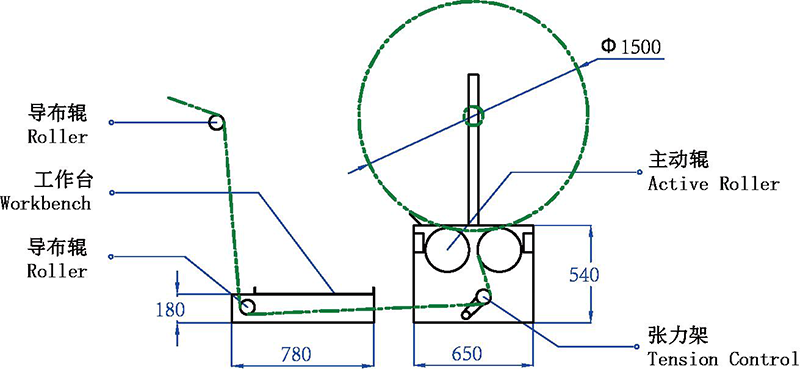

| Maximum winding diameter | 1500mm |

| Working width | 1500-3200mm (can customized) |

| Diameter of roller | 220.270mm (can customized) |

Our professional team will give you the best suggestion as long as you tell us what kind of test you need to do andthe required specification.

At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15~20 working days after deposit receipt. If you are in urgent need, we can consider making special arrangement for you.

Yes, of course, we can not only offer standard machines, but also customized machines according to your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to arrange hotel and pick up you from airport.

Now our testing machines have been sold to more than 80 countries, like USA, Canada, Russia,UK, Italy, Germany, European ,India,Pakistan, Philippine, Singapore, Malaysia,Thailand , Vietnam, Korea,Saudi Arabia,Brazil…and so on.

Generally,our warranty is one years. Within the warranty period, we can offer technique support and part parts change, necessarily, our engineers may go to your place for better service.

Our machine is packed by standard export wooden box, it won’t be damaged. We’ve delivered many testing machines abroad by sea or by air without damage.

Inquiry – quotation – communication – order confirming – deposit payment – production – testing and debugging – balance payment-packing – delivery – customer receiving – after service.

The product is shipped with an operating instructions and video of English version.

With the continuous improvement of the functional requirements of textile finishing machines in various countries, the structures and functions of our fabric inspection machines, fabric slitting machines, and fabric folding machines are constantly being adjusted.