RH-500 Automatic Fabric Spreader

Short Description:

|

① MORE INTELLIGENT

High reliability touch screen, new type communication technology and high electromechanical integration design make machine realize high itelligence.

② MORE EFFICIENT

New type integrated side frames, the beating-up mechanism with good balance performance, and the excellent weft insertion system complement each other, applicable to various yarn counts, and at the same time help realize the weaving of high-speed, low vibration and high quality.

③ MORE CONVENIENT

Full consideration of the convenience for the operation of workers in the course of design, external loose warp device, automatic central oil supply system,and friendly man-machine interface make machine more humanization, and embody the superiority in the course of application.

④ MORE ENERGY SAVING

New type energy-saving weft insertion system, shorten air path, increase jet sensitivity and reduce air consumption.

|

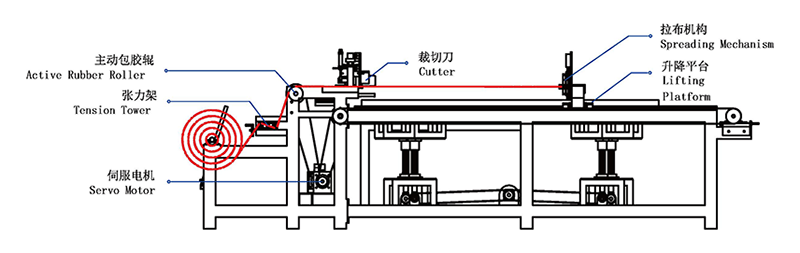

Technical Features

1, PLC control LCD touch system: choosing or setting functions only by touching the function keys on the touch screen

2,The machine can set up the amount of layers (maximum 100 layers). When the layers reaches the preset number or no cloth will automatically shut down

3, Keep feeding and spreading fabrics without tension, no cloth stretching phenomenon appeared

4, Functions of machine can be set up simply. Single person can operate, save manpower, without manual intervention

5,Equipped with the emergency stop device. The fabric that is spreading not appears dragging case when stop

6,The path of cloth cutting knife can be adjustable depend on width of fabrics. It can save extra time in the progress of moving back and forth

7,Automatic edge-align device assure the selvage neatly, saving fabrics

8, Humane emergency stop devices to prevent sudden security maintenance

9, Suitable for knitted fabrics, woven fabrics, pre-shrinking fabric cloth, one-way spreading

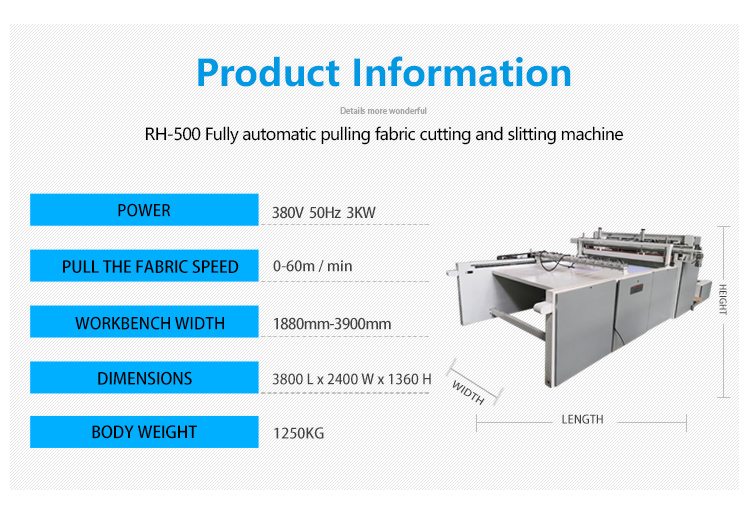

Technical Parameters

| Fabric width | 1500mm-3500mm |

| Table width | 1880mm-3900mm |

| Spreader speed | 0-60 m/min |

| Weight | 1250 KG |

| Power | 380V(50Hz/60Hz) 3KW |

| Dimension | 3800mm*2400mm*1360mm |

Our professional team will give you the best suggestion as long as you tell us what kind of test you need to do andthe required specification.

At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15~20 working days after deposit receipt. If you are in urgent need, we can consider making special arrangement for you.

Yes, of course, we can not only offer standard machines, but also customized machines according to your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to arrange hotel and pick up you from airport.

Now our testing machines have been sold to more than 80 countries, like USA, Canada, Russia,UK, Italy, Germany, European ,India,Pakistan, Philippine, Singapore, Malaysia,Thailand , Vietnam, Korea,Saudi Arabia,Brazil…and so on.

Generally,our warranty is one years. Within the warranty period, we can offer technique support and part parts change, necessarily, our engineers may go to your place for better service.

Our machine is packed by standard export wooden box, it won’t be damaged. We’ve delivered many testing machines abroad by sea or by air without damage.

Inquiry – quotation – communication – order confirming – deposit payment – production – testing and debugging – balance payment-packing – delivery – customer receiving – after service.

The product is shipped with an operating instructions and video of English version.

With the continuous improvement of the functional requirements of textile finishing machines in various countries, the structures and functions of our fabric inspection machines, fabric slitting machines, and fabric folding machines are constantly being adjusted.