RH-400A Slitting Machine With Hot Cutter

Short Description:

This machine is widely used in the production area of lace, garment processing, embroidery, banners production, packaging, gift processing, footwear processing, packaging etc.

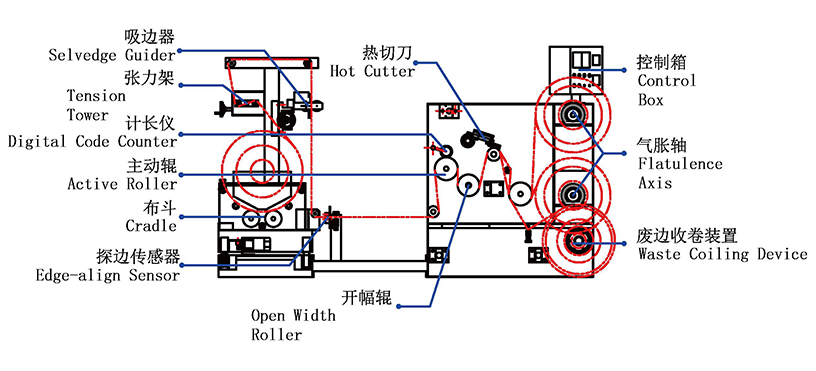

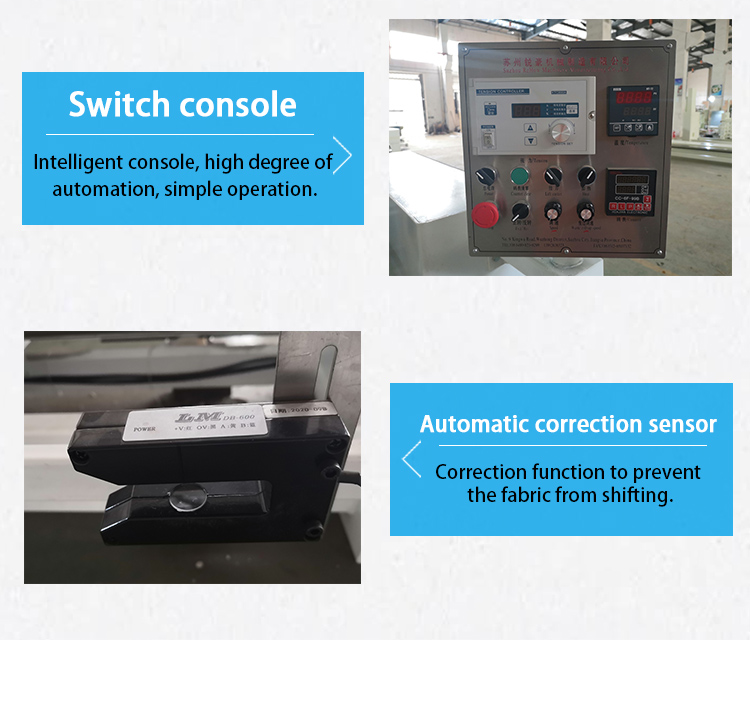

Technical Feature:

1. The dimension of stripes can be adjustable convenient and efficient. You can choose any width of each section on the basis of minimum width. 2. The vertical structure of slitting cutter is humanistic. It can make the influence on heating caused by slitting process reduce to a minimum 3. Equipped with an electronic controller, this device can control the cutter heating , and also heighten an effect of energy saving

4. The machine adopts infrared rays guiding system to make the fabrics slitting neatly and trimly and decrease scrap to a great extent

5. The cutter of this machine is made of tungsten steel alloy, with which after special processing. The machine can be using much longer time by these cutters. At the same time of slitting, temperature can steal the fabric edges, so that no excess fabric irregular edges produced and no charred fabric leave

6. The newly designed feeding basket together with a transition device which could make slit conveniently both for rolled and flat form of fabrics

7. Compact mechanical design of the machine make greatly reduced footprint, thus saving space

Technical Parameters:

| 1. The maximum cutting width | 1800-3200 mm |

| 2. The minimum slitting width | 10 mm |

| 3. Maximum cutting speed | 0-40m/min(depend on the material) |

| 4. Power | 5kw(depend on the amount of cutters) |

| 5. Voltage | 380V |

| 6. Weight | 1500 kg |

| 7. Dimension | 2800mm×2400mm×1600mm |

Our professional team will give you the best suggestion as long as you tell us what kind of test you need to do andthe required specification.

At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15~20 working days after deposit receipt. If you are in urgent need, we can consider making special arrangement for you.

Yes, of course, we can not only offer standard machines, but also customized machines according to your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to arrange hotel and pick up you from airport.

Now our testing machines have been sold to more than 80 countries, like USA, Canada, Russia,UK, Italy, Germany, European ,India,Pakistan, Philippine, Singapore, Malaysia,Thailand , Vietnam, Korea,Saudi Arabia,Brazil…and so on.

Generally,our warranty is one years. Within the warranty period, we can offer technique support and part parts change, necessarily, our engineers may go to your place for better service.

Our machine is packed by standard export wooden box, it won’t be damaged. We’ve delivered many testing machines abroad by sea or by air without damage.

Inquiry – quotation – communication – order confirming – deposit payment – production – testing and debugging – balance payment-packing – delivery – customer receiving – after service.

The product is shipped with an operating instructions and video of English version.

With the continuous improvement of the functional requirements of textile finishing machines in various countries, the structures and functions of our fabric inspection machines, fabric slitting machines, and fabric folding machines are constantly being adjusted.