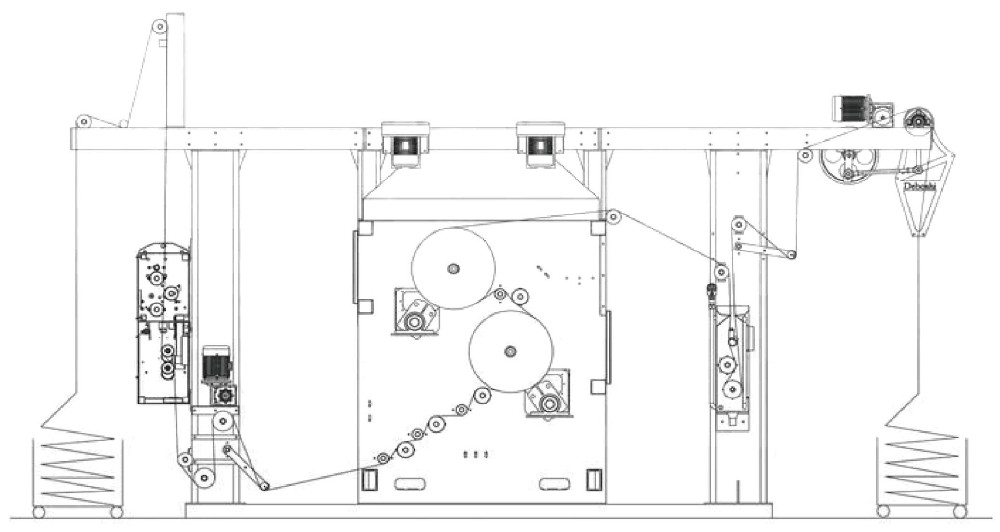

RH-300 Open-width Knitted Fabric Singeing Machine

Short Description:

The burner nozzles are exquisitely made, and a circulating cooling tube is equipped at the burner to keep it working for a long time and ensure the evenness of the fire. The service life can reach as long as five years, and the power consumption is reduced by 50%, which greatly lowers the manufacturing cost.

Product Introduction:

The requirement on the grades of knitted fabrics becomes higher and higher. The singeing process of knitted fabrics is very important. Especially for the recently popular elastic cloth racking process, if singeing is added, the cost will be greatly reduced and the strength and cloth surface effects will be improved. This product adopts the features of similar products and uses MJA burner. The burner nozzles are exquisitely made, and a circulating cooling tube is equipped at the burner to keep it working for a long time and ensure the evenness of the fire. The service life can reach as long as five years, and the power consumption is reduced by 50%, which greatly lowers the manufacturing cost.

Technical Features:

1. Compact structure, and the distance between the rollers is small.

2. All the rollers except the transition rollers are dynamic rollers with decreases the tension and avoid corrugation.

3. PLC control and frequency conversion speed regulation ensures a stable synchronism and avoids corrugation.

4. The machine frames and rollers have high mechanical strength, together with small fit tolerance and stable transmission to avoid corrugation.

5. Multiple S type transmission and thread separation avoid corrugation and peeling and ensure even singeing.

Technical Parameters:

| 1. Vehicle distinction | Left, right |

| 2. Width | 2400mm |

| 3. Thermal source | gasoline, natural gas and oil gas |

| 4. Power consumption | Take gasoline and 2,200 mm width machine as an example: 10L /h |

| 5. Speed | 40 to 100 m/min |

| 6. Environment protection | equipped with dust removal device; up-to-standard, no pollution and low noise |

| 7. Ways of singeing | counter-singeing, cutting and singeing |

| 8. Span adjustment | 570 cooling cylinder adjustable |

| 9. Break point treatment | the burner turns to other direction automatically |

| 10. Forms of cooling | steam, water |

| 11. Singeing level | above level 4 |

| 12. Motor power | 14.8KW |

| 13. Dimension (L*W*H) | 7500*4200*3300mm |

Our professional team will give you the best suggestion as long as you tell us what kind of test you need to do andthe required specification.

At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15~20 working days after deposit receipt. If you are in urgent need, we can consider making special arrangement for you.

Yes, of course, we can not only offer standard machines, but also customized machines according to your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to arrange hotel and pick up you from airport.

Now our testing machines have been sold to more than 80 countries, like USA, Canada, Russia,UK, Italy, Germany, European ,India,Pakistan, Philippine, Singapore, Malaysia,Thailand , Vietnam, Korea,Saudi Arabia,Brazil…and so on.

Generally,our warranty is one years. Within the warranty period, we can offer technique support and part parts change, necessarily, our engineers may go to your place for better service.

Our machine is packed by standard export wooden box, it won’t be damaged. We’ve delivered many testing machines abroad by sea or by air without damage.

Inquiry – quotation – communication – order confirming – deposit payment – production – testing and debugging – balance payment-packing – delivery – customer receiving – after service.

The product is shipped with an operating instructions and video of English version.

With the continuous improvement of the functional requirements of textile finishing machines in various countries, the structures and functions of our fabric inspection machines, fabric slitting machines, and fabric folding machines are constantly being adjusted.