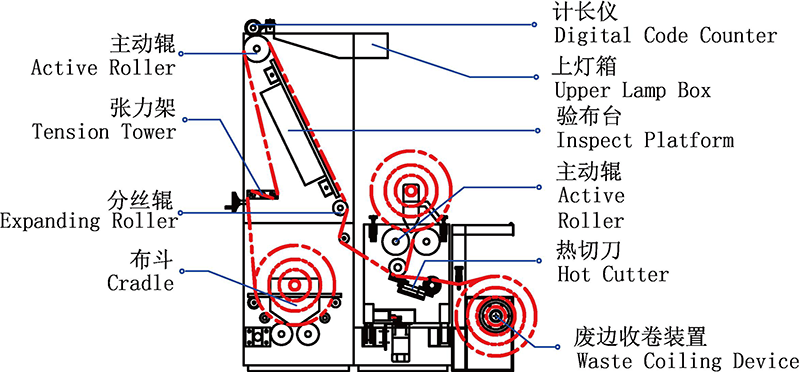

RH-218 Edge Cutting Inspection Rolling Machine

Short Description:

Application:

The fabric inspection machine is for chemical fiber fabrics, nonwoven fabrics, wire-mesh cloth, after inspection, trims directly into the tube packs. It can also be used by more knife-cut take-up, or for post-mortem volume of direct coiling.

Technical Feature:

1、Good performance with high quality

2、Use double-frequency control to adjust tension, both thick and thin fabric can adapt

3、Equipped with a photoelectronic exploration device, to which promote edge accuracy

4、Use computer counter to calculate the length and the yard of fabrics

5、Adopted the light device to enhance inspection quality

6、Clod cut, the aerodynamic configuration cold cutter, through the air pressure to control, adjust the knife pressure-thick, thin may apply

7、Hot cut, targeted vertical electric heating knife, only 180W single/double-throw power control and temperature control regulator combination, in accordance with requirements of self-regulation and control settings

Technical Parameters:

| 1、Effective width | 1800mm~3500mm(optional) |

| 2、Winding diameter | 480mm |

| 3、Take-up speed | 0~60 m/min |

| 4、Correcting category | Hydraulic typephotoelectric probe |

| 5、Tension adjustment | 0~400n |

| 6、Power | 1.5~2.21kw |

| 7、Weight | about 1000KG |

| 8、Dimension | 1350(L)*2800(W)*2000(H)mm |

With the continuous improvement of the functional requirements of textile finishing machines in various countries, the structures and functions of our fabric inspection machines, fabric slitting machines, and fabric folding machines are constantly being adjusted.