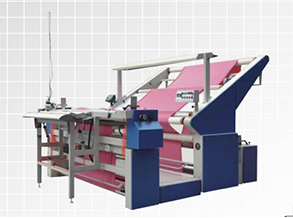

The tension-free cloth winding machine produced by rehow company is a precision machine, which can solve the problems of wrinkles and waves that may occur during the winding process, and ensures the stability of the winding quality. The application range of this machine is very wide, covering many industries such as textile, printing, electronics, medical treatment, aviation and so on. This article will introduce in detail the principle, advantages and disadvantages of the tensionless cloth winder, as well as some matters needing attention in practical application.

1. Principle

The tension-free cloth winding machine uses sensors and sensors to control the tension of the cloth to prevent the problem of excessive or too small tension during the winding process. Specifically, the tension-free cloth winding machine can be regarded as composed of the following parts:

1. Fabric winding shaft: the axis used to wind the fabric.

2. Transmission mechanism: used to rotate the cloth take-up shaft, driving the cloth to enter from one end and exit from the other end.

3. Tension sensor: used to detect the tension of the fabric during the winding process, and feed the data back to the controller.

4. Controller: According to the feedback information of the tension sensor, control the speed of the motor to keep the tension within a certain range.

2. Advantages

1. It can avoid uneven tightness. For some textiles, due to the stretch and elasticity during processing, it is often difficult to ensure uniform tightness during winding, and the tension-free cloth winding machine can reduce the occurrence of this situation, thereby improving the quality of winding.

2. Can improve efficiency. Since there will be no uneven tension when winding the cloth, the machine can work continuously, and there is no need to stop regularly to check the tension of the winding like traditional cloth winding machines, so it has advantages in production efficiency.

3. Can save labor costs. Traditional cloth winding machines often require personnel to manually adjust the winding tension, while tension-free cloth winding machines can automatically control the tension, so manual intervention is not required, which can save a certain amount of labor costs.

3. Disadvantages

1. High equipment cost. Tensionless cloth winders have more complex control systems and sensors, so their manufacturing costs are higher than traditional cloth winders.

2. It is difficult to maintain. Because the device is more sophisticated, it is also more difficult to maintain and maintain.

3. High requirements on fabrics. The machine is suitable for smoother and looser fabrics, so the quality and characteristics of the fabric need to be considered.

4. Matters needing attention

1. It is necessary to overhaul the machine before use to ensure that all sensors and controllers are in normal operation and operate in strict accordance with the operating instructions.

2. During the winding process, care should be taken to avoid overloading, and the tension should be properly adjusted according to the characteristics of the fabric.

3. Carry out maintenance and maintenance frequently, clean sensors and controllers, and lubricate and inspect key parts.

4. Deal with the faults in time. For some complicated problems, it is best to have them repaired by professionals.

In short, as a new type of winding machine, the tensionless cloth winder has great advantages, but it also has certain disadvantages. In actual use, you need to consider and choose according to the specific situation, and you also need to pay attention to the relevant maintenance and maintenance work

If you want to buy a tension-free cloth winding machine, you can find rehow machinery. Rehow textile machinery company is worthy of your trust. Rehow company is specialized in textile machinery manufacturing and is committed to providing high-quality mechanical equipment and technical solutions for the global textile industry. REHOW has an efficient and professional service team, committed to providing customers with high-quality consultation and after-sales service.

It mainly produces high-speed looms, cloth inspection machines, cloth packaging machines and other textile equipment. We have independent research and development capabilities and a complete quality management system. All products have undergone strict quality testing and certification to ensure product stability and reliability.

Post time: May-06-2023