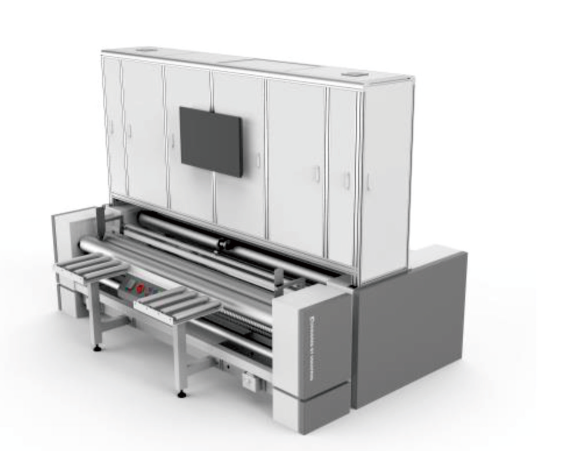

rehow automatic cloth inspection machine consists of an intelligent information collection terminal and information synchronization equipment, as well as a management software system on the equipment side and the computer side. The intelligent cloth inspection machine installs AI software on the traditional cloth inspection machine, which can realize the quick collection of cloth inspection information, real-time sharing of cloth information and easy printing of cloth labels. As a reconstruction and intelligence of the traditional cloth inspection method, the automatic cloth inspection machine can be regarded as a model of modern industry 4.0.

The automatic cloth inspection machine is installed on the cloth inspection machine, which automatically reads the location information of the cloth and synchronizes it with the inventory computer. The cloth inspector only needs to click on the keyboard of his partner when he encounters a defect, and the defect information can be automatically entered and synchronized to the computer. After the cloth inspection is completed, the cloth barcode is directly printed and posted on the cloth.

The advantages of using the AO-AI model automatic cloth inspection machine produced by REHOW are as follows:

1. Greatly simplifies the input procedure of cloth inspection and improves the efficiency of cloth inspection

2. On-site keyboard input by fabric inspectors, greatly reducing the error rate of information

3. The system automatically matches the cloth information with the staff, and any problems in the future can be traced back to the staff

4. The cloth information printed by the equipment can be put into and out of the warehouse by scanning the barcode, and the cloth management is simple and orderly

5. The inventory computer automatically synchronizes the cloth inspection information, and it is easy to understand the inspection amount and completion amount of the cloth

rehow automatic cloth inspection machine product features:

Record defect points: Workers can easily enter information such as the defect location and name of the cloth through the software system of the automatic cloth inspection machine, and automatically calculate the cloth grade through the equipment

Defect collection

Same data: Through the inventory server connected to the automatic cloth inspection machine system, the cloth information and defect information are synchronized to the server to realize the data synchronization and sharing of cloth inspection information.

information submission

Labeling: After the inspection of each roll of cloth is completed, the printer and automatic cloth inspection machine connected to the equipment will print out the label of the cloth to realize the flow of cloth information.

print label

Manage the warehouse: use the code scanning gun to scan the code on the label posted on the cloth, easy to enter and exit the warehouse

Product value of automatic cloth inspection machine:

Labor saving: through the automatic cloth inspection machine software system, the defect information of the cloth can be easily entered and synchronized to the inventory server, eliminating the need for manual recording by on-site personnel and manual entry by inventory personnel. Effectively reduce the manual dependence of cloth inspection information input. According to the data analysis after the customer’s actual installation, by installing the rehow cloth inspection machine software system, the same workload can save 2-3 workers in the factory

Improve efficiency: The input speed of on-site equipment has been greatly improved. At the same time, the storage, storage, and management of cloth can be quickly completed through scanning codes and computer management. Greatly improve the efficiency of cloth management. According to the data analysis after the customer’s actual installation, the efficiency of cloth inspection and inventory management can be increased by more than 30%.

Refinement: Through the printed cloth label, the fine management of cloth information can be realized, which can effectively avoid the occurrence of unclear cloth status and cloth loss. According to the current customer statistics after installation, the management of cloth can achieve 100% no loss.

Traceability: Through the digital management of cloth inspection, input, storage, and delivery, each step is corresponding to the person, and traceable data support is provided for post-event responsibility analysis and workload calculation. According to the data analysis after the customer’s actual installation, the workload and process management can be fully traced without omission!

Automatic cloth inspection machine product features:

1. The equipment is easy to operate, keyboard input, easy to use

2. The equipment is easy to install, and the fixing bracket is directly fixed on the cloth inspection machine

3. Specially designed for cloth field, stable and reliable quality

4. The system structure is simple, no complicated information entry is required, and the report is simple and clear

rehow automatic cloth inspection machine product operation process:

1. Print the process sheet: print out the order number and other information corresponding to the cloth to be inspected in the form of a process sheet, and the software will automatically generate the barcode and ID number

2. Log in as a fabric inspector: the fabric inspector turns on the device switch, enters the job number and password, and enters the fabric inspection interface

3. Process order synchronization: scan the process order, or manually enter the process order number, and enter the fabric inspection state

4. Defect entry: When encountering a defect, the fabric inspector directly clicks on the keyboard to enter the name of the defect, and deducts the points. After confirmation, the information is automatically synchronized to the computer.

5. Print barcode: After the inspection of a piece of cloth is completed, the equipment will automatically generate a barcode of information such as the grade of the cloth, click to print out the barcode and paste it on the cloth.

6. Inbound and outbound management: Just scan the barcode posted on the cloth directly through the barcode gun, and the outbound and inbound of the cloth can be realized automatically

Automatic cloth inspection machine equipment installation six steps:

1. Fix the wall-mounted bracket of the cloth inspection input terminal on the upper right of the cloth inspection machine, as shown in the figure below

2. Connect the inventory server: Lay an RJ45 network cable between the inventory computer and the equipment, connect one end to the RJ45 interface of the equipment, and connect the other end to the network cable port on the computer. If the computer has only one network port, you can add a router Or a switch; if there are multiple cloth inspection machines, several devices can be connected to a switch nearby, and then connected to the computer through a network cable.

3. Connect the printer: connect the USB port of the printer to the printer port of the device

4. Connect the scanner (optional): connect the scanner to the scanner interface of the device

5. Connect the rolling code table of the cloth inspection machine: use the data cable to connect the roller type cloth length acquisition interface of the equipment and the rolling code table of the cloth inspection machine

6. Insert the power plug into the 220V power socket to realize the normal operation of the equipment

Product advantages of ReHow automatic cloth inspection machine:

Firmly grasp the key link of cloth inspection: through the easy entry of information such as cloth defects by the input equipment, the digitization of cloth information is realized.

Realize the natural flow of cloth information: After each roll of cloth is inspected, print out the cloth label through the printer connected to the input terminal and stick it on the cloth. In the storage, delivery, and sales of cloth, you can scan the code Easy to do.

Realize the digital management of cloth status, cloth quality characteristics and quality grades: with the help of the inventory server connected to the cloth inspection machine partner/cloth inspection data entry terminal, the cloth information can be obtained synchronously. Through the on-site management software installed on the inventory server, the data management of cloth status, cloth quality characteristics and quality grades, etc. is realized.

Through the application of industrial control automation technology, rehow machinery mainly realizes the detection of instruments and meters through control and computer information technology, which can better reduce the corresponding detection means, and meet its output and reduce energy consumption through control and adjustment means . Due to the large-scale application of automation technology in the textile industry, it can change the production energy efficiency of enterprises after technological innovation matures

Post time: May-08-2023