REHOW cloth inspection machine is a set of necessary special equipment for inspection of cotton, wool, linen, silk, chemical fiber and other large-format, double-width and single-width cloth before production in the garment industry.

The types of REHOW cloth inspection machines include: cloth inspection machine, knitting cloth inspection machine, woven cloth inspection machine, tension-free cloth inspection machine, multi-function cloth inspection machine, needle and shuttle dual-purpose cloth inspection machine, denim cloth inspection machine, comb Weaving machine.

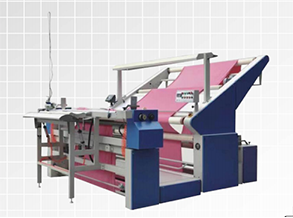

图1:Knitting cloth inspection machine

Cloth inspection machine configuration: frequency conversion stepless speed regulation, high-precision intelligent electronic measuring coder, liquid crystal display data, electric eye automatic edge alignment, electric eye monitoring cloth release, non-fabric shutdown, combing and curling cloth shaft, front-rolling and rewinding cloth, Up and down lamp panel, electronic tension adjustment, emergency stop switch, universal casters.

Product features of cloth inspection machine:

1. The cloth inspection machine adopts the combination technology of two-way signal detection circuit, and the cloth inspection machine has high sensitivity and high anti-interference ability.

2. With dual signal display function. When a metal object passes through, the signal level indicator will display different induction strengths according to the size of the metal.

3. Signal processing is completed by digital circuit, easy to adjust, stable and reliable.

4. The food metal detector has a product effect adjustment function, and 10 levels of independent adjustment for ferrous metals and non-ferrous metals.

5. The cloth inspection machine has the function of leak-proof inspection. When multiple metal signals pass through, the instrument will automatically detect the number of signals, and the actuator will not miss when it moves.

6. When no detected object passes, the cloth inspection machine is in a sleep working state, and the detection is valid only when the object passes.

7. It can be used in conjunction with the assembly line to implement automatic detection of the assembly line.

8. The food metal detector detector adopts sound and light alarm and stops, and the operation of the cloth inspection machine is extremely convenient and reliable.

REHOW Textile Machinery Company has an efficient and professional service team, committed to providing customers with high-quality consultation and after-sales service. REHOW has always been adhering to the business philosophy of “integrity, quality, innovation, and win-win” to create a better future hand in hand with customers.

Post time: May-16-2023