Fabric Cutting Machine Manufacturing Materials

The materials used in the manufacturing of fabric cutting machines can vary depending on the specific type and model of machine being produced. However, some common materials used in the fabrication of these machines include:

Steel: Many parts of the fabric cutting machine, including the frame, blades, and cutting surfaces, are often made from high-strength steel to provide durability and stability.

1.Aluminum:

Some parts of the machine, such as the cutting table and accessories, may be made from lightweight aluminum to reduce overall weight and improve portability.

2.Plastics:

Various types of plastic materials, such as polycarbonate, are often used for the machine’s protective covers, handles, and other non-structural parts.

3.Electronics:

Depending on the type of fabric cutting machine, electronic components such as motors, sensors, and controllers may be used in the manufacturing process.

4.Hardware:

Various types of hardware, such as nuts, bolts, and screws, are used to assemble the different parts of the fabric cutting machine.

5.Lubricants:

To ensure smooth operation of the machine’s moving parts, lubricants such as oils and greases are used during the manufacturing process.

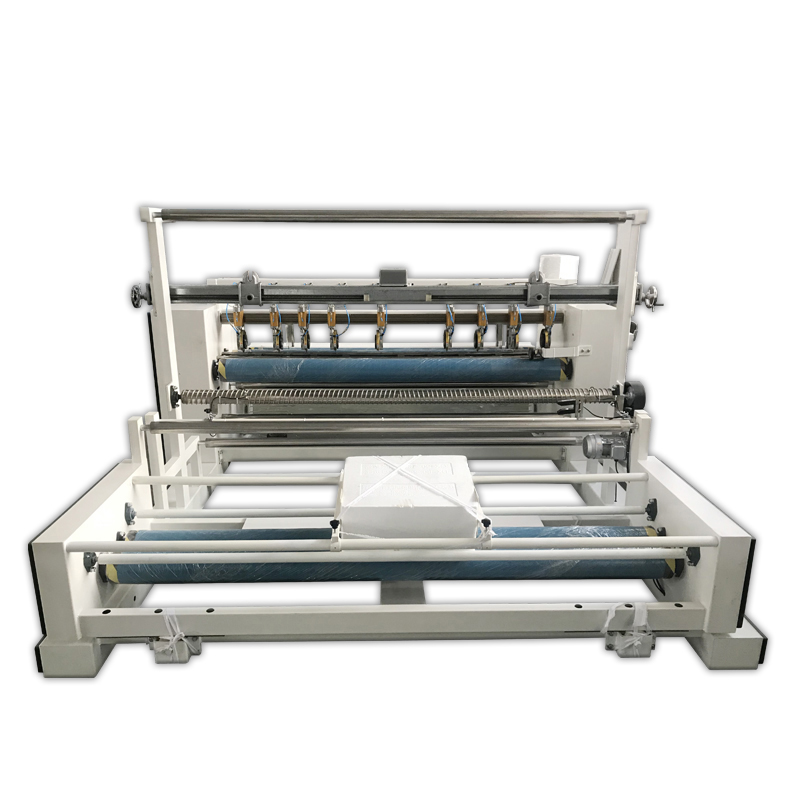

Structure of Fabric Roll Cutting Machine

A fabric cutting machine is a specialized device used in the textile industry to cut fabric into desired shapes and sizes. The structure of a fabric cutting machine may vary depending on the type of machine, but most machines have some common components. Here are the basic parts of a fabric cutting machine:

1.Cutting table:

The cutting table is a flat surface where the fabric is laid out for cutting.

2.Cutting blade:

The cutting blade is the main cutting tool of the machine, which is used to cut the fabric. There are different types of cutting blades, such as circular blades, straight blades, and rotary blades.

3.Cutting head:

The cutting head is the part of the machine that houses the cutting blade. It can be manually operated or computer-controlled.

4.Clamp:

The clamp is used to hold the fabric in place on the cutting table during cutting. It helps to prevent the fabric from shifting or wrinkling during the cutting process.

5.Feed mechanism:

The feed mechanism is responsible for moving the fabric across the cutting table to ensure accurate and consistent cutting. It can be manual or automatic.

6.Control panel:

The control panel is the interface between the operator and the machine. It is used to set the cutting parameters, such as the cutting speed, blade pressure, and cutting depth.

7.Dust collection system:

Fabric cutting machines generate a lot of dust and debris during the cutting process. A dust collection system is used to remove the dust and keep the work area clean.

Conclusion

Overall, the materials used in the manufacturing of fabric roll cutting machine is selected based on their properties and the specific requirements of the machine, and the structure of a fabric roll cutting machine is designed to provide a stable and efficient platform for cutting fabric quickly and accurately. Learning something about the manufacturing material and structure of a fabric roll cutting machine is helpful for manufacturers to choose their ideal product.

REHOW provides the textile industry machines to the whole world, helps them to improve the efficient, decrease the labor costs. REHOW offers numerous types of textile machinery: fabric inspection machine, fabric cutting machine, beam truck, trolley lift, fabric rolling machine etc. If you are interested in us, please contact us now!

Post time: Mar-23-2023