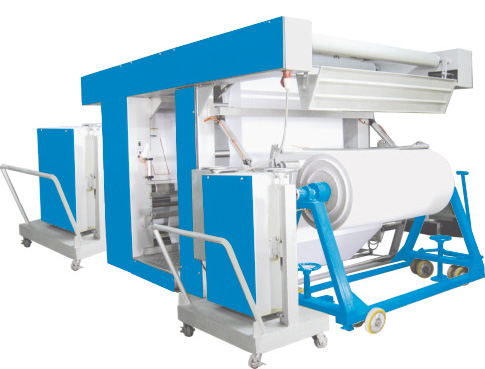

The widespread use of cloth inspection machines has driven the rapid development of the textile industry. For the rehow cloth inspecting machine, the conveyor belt is a very important part. If there is a problem with it, it will cause problems to the cloth inspecting machine. So, let’s talk about the correct operation and cleaning methods of the conveyor belt of the cloth inspection machine.

rehow the use of cloth inspection machine conveyor belt

1. Adjust relevant equipment in time according to the operation of the conveyor belt to avoid belt deflection that will increase the wear of the belt edge and damage the upper and lower cover plates, exposing and separating the wire rope.

2. Remove the attachments on the surface of the driving roller in time to avoid joint foaming due to the irregular shape of the roller surface, distortion of the steel wire rope, elongation of the vulcanized joint, etc. joint strength.

3. The vulcanized joint is the weak part of the belt strength. Joint openings are characterized by rubber breaks. Water soaks into the wire rope through the gap of the core rubber, causing the wire rope to rust, break the wire rope and convulse. Joints should be regularly checked for elongation changes, abnormal surface changes, etc., and preventive checks should be made to correct defective joints.

4. If there is belt edge glue, cover glue falls off, steel wire rope and other defects are exposed, cold glue or vulcanization heat compensation should be carried out in time. According to the partial defects of the conveyor belt, choose different maintenance methods (such as cold compensation, hot vulcanization and wire rope filling) to keep the conveyor belt surface intact.

False alarms will appear after the cloth inspection machine is used for a long time, usually because the conveyor belt is polluted by dust, so it is necessary to clean the conveyor belt regularly, how to clean it?

1. Turn off the machine, and then turn the function button switch to “Type C”.

2. At the end of the rack, behind the door frame, place a wet towel under the belt shaft, the towel at the other end will wear out. Use both hands to tighten the end of the towel so that the towel fits snugly against the belt.

3. Turn on the machine, run the conveyor belt, and then wipe the inside of the running conveyor belt with a wet towel.

4. If necessary, remove the covers and panels on both sides of the machine, and wipe the inside of the belt with a wet towel.

The exact wiping method is as follows: put a wet towel under the conveyor belt and wipe it 20 cm below the conveyor belt. Hold the end of the towel tightly and place the towel on the inside of the belt. Then turn on the C engine with the belt running and wipe down the inside. The direction of force is on both sides of the machine, so that the towel in the hand is balanced with the conveyor belt or the same line. This wiping method can clean the belt in all directions.

REHOW Textile Machinery is a company specializing in textile machinery manufacturing, and is committed to providing high-quality mechanical equipment and technical solutions for the global textile industry.

It mainly produces high-speed looms, cloth inspection machines, cloth packaging machines and other textile equipment. We have independent research and development capabilities and a complete quality management system. All products have undergone strict quality testing and certification to ensure product stability and reliability.

REHOW provides textile industrial machines to the whole world, helping them improve efficiency and reduce labor cost. REHOW provides various types of textile machinery: raising machine, cloth inspection machine, packaging machine, coiling machine, slitting machine, cross cutting machine, ribbon weaving machine, weaving machine, etc. If you are interested in us, please contact us now!

Post time: May-04-2023