one. use:

VS-E Rope Untwisting and Open Width Machine: It is used for rope (bundle) scouring, bleaching, dehydration after dyeing, (water tying), untwisting, open width (open width water absorption) drying, shaping, etc. for fabrics in the printing and dyeing industry. Indispensable special equipment in the process.

two. The main technical parameters:

1. Machine width: 2000-3400 (limited to the length of the stick)

2. Design speed: 20-100m/min

3. Process speed: 25-75m/min.

4. Cloth feeding and falling: Rope feeding, open width falling.

5. Untwisting method: automatic untwisting, or manual untwisting

6. Centering device: two rods for photoelectric centering, three rods for infrared alignment, and the driving form is electric or pneumatic.

7. Machine power: 6–8kw

8. Dimensions: 200 type 2800x2760x7000mm (length x width x height)

340 type 2800x160x10000mm (length x width x height)

three. Structural features and principles of the machine:

1. Untwisting device: It is composed of three roller groups, spoke guide wheels, detection rollers, proximity switches, brake motors, etc. The fabric is clamped by the three roller groups, and the spoke guides are bounded, and then the twist direction of the fabric is detected by the side rollers. During operation, due to the force of the twist, the detection roller moves in two different directions, close to the proximity switch, so that the two opposite angle proximity switches act, and output the positive twist or reverse twist signal to the controller, so as to control the forward or reverse rotation of the motor. The false twist formed by the reversal is opposite to the direction of the twist of the fabric, pushing out the twist on the fabric.

2. Stretching device: use a stretcher with a suitable helix, the stretcher roller rotates in the opposite direction to the fabric running direction, the speed of the stretcher roller is slightly overspeed than that of the mop roller, even when the fabric is running at a low speed, the stretcher roller will It will not scratch the fabric and maintain the stretch effect of the fabric.

3. Centering device: mainly composed of infrared sensor, correction roller, pneumatic valve and the above-mentioned spreader device. The infrared sensor is composed of infrared emitting and receiving components and is used for protection and management. In the working room, the progressive fabric is placed in the gap between the two protective tubes. When the central position of the fabric deviates from the central axis, the infrared sensor will output a signal to the electrical control system to command the action of the deviation correction mechanism so that the central position of the position is still returned to At the position of the central axis, the deviation correction function is achieved.

4. Beater device: it mainly loosens the fabric and prevents loose twisting, which is beneficial to stretching.

5. Cloth falling device: It consists of a mopping roller and two special doffing rollers. Two sets of four-plane connecting rods are arranged in two parallel planes, so that the fabric falls into the cloth car with an appropriate folding size. . (Xieke can design the cloth falling and rolling device).

6. Transmission mechanism: The transmission adopts the internationally popular AC motor frequency conversion speed regulation technology. According to different models, a 3.7-5.5 kW frequency conversion speed controller is selected to control the main motor (width 0.75) to drive the mop roller and cloth falling device through chain transmission. , the actual collective transmission. (The model structure is constantly updated, the above is for reference only)

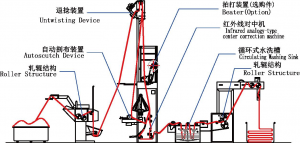

Four. Schematic diagram of VS-E rope untwisting open width machine:

Use ofVS-E Rope Untwisting Open Width Machine

1. Regularly clean, check the rotating parts of each part, whether there is any defect or oil leakage, so as to avoid the parts from being worn or damaged due to lack of oil, whether there is any abnormal sound, and solve the problem in time.

2. Before starting the machine, check whether the machinery, electricity, expansion device, and infrared centering device of the machine are in good condition; whether the climbing ladder to the untwisting head is safe and firm.

3. When starting, first turn the automatic and manual knob switch of the untwisting device to the manual position, and when the fabric enters the untwisting device and the running speed increases slightly, turn the switch back to the automatic position.

4. The fabric seams must be sewn with a sewing machine, and cannot be connected with knots, so as not to damage the detection parts of the untwisting device.

5. The sliding shaft of the detection roller of the untwisting device must be cleaned and lubricated before the shift, and check whether the proximity switch is loose to ensure that the detection roller slides sensitively.

6. The expansion device should adjust the size of the wrapping angle according to different types of fabrics. When choosing the wrapping angle, it should be small rather than large, and moderate tension in the weft direction is enough. Be careful not to touch the helical surface of the roll body with your palm when the spreader roll is running.

7. The infrared probe is strictly prohibited from soaking in water. After wearing the cloth, adjust the left and right distance of the infrared probe to detect objects, keep the fabric in the center, and automatically adjust when the door width is different.

8. Use the guide belt to thread the fabric, and be careful when you have to go up the ladder to prevent falling from high altitude.

Post time: May-25-2023