When the slitting machine is cutting at high speed, the main reason for the damage of the round blade of the slitting machine is that it is caused by mechanical friction, bonding, chemical wear, chipping, crushing and plastic deformation under the action of cutting force and cutting temperature. of wear and tear.

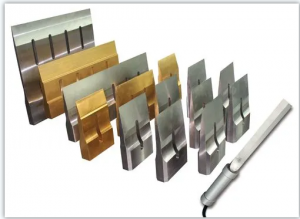

图:Slitting machine blade

The wear patterns of circular blades in high-speed cutting of slitting and slitting machines are analyzed. High-speed milling is a process of intermittent cutting. Various high-speed cutting circular blade materials (including ceramic cutters, cubic boron nitride circular blades, diamond circular , cermet circular inserts and coated circular inserts) wear mechanism during high-speed cutting, and discussed the wear life of circular inserts during high-speed cutting of cast iron, hardened steel and nickel-based alloys.

During the high-speed cutting process of the slitting and slitting machine, the ceramic circular blade, the change rule of the cutting force and the influence of the cutting amount on the cutting force are of great importance for revealing the cutting deformation mechanism of the high-speed cutting process, improving the surface quality of the workpiece and increasing the life of the circular blade. theoretical significance and practical application value. The wear mechanisms of cubic boron nitride round inserts, diamond round inserts, cermet round inserts and coated round inserts are comprehensively reviewed, and the wear patterns and wear life of the tools are analyzed. These studies will be beneficial to the actual production process. Reasonable selection and wear control of high-speed cutting tools for slitting and slitting machines.

REHOW Textile Machinery

An enterprise specializing in textile machinery manufacturing, it is committed to providing high-quality mechanical equipment and technical solutions for the global textile industry.

Mainly produce fabric slitting machines, high-speed looms, cloth inspection machines, cloth packaging machines and other textile equipment. We have independent research and development capabilities and a complete quality management system. All products have undergone strict quality testing and certification to ensure product stability and reliability.

Post time: May-16-2023