REHOW Machinery specializes in the development and manufacture of screen printing machinery and auxiliary equipment and training in screen printing technology; since its establishment, it has trained a group of professionals in the design and manufacture of screen printing machinery and established a set of professional pre-sales/after-sales services for screen printing products. Service talent team; it is a professional enterprise dedicated to the design and manufacture of high-precision, automated and intelligent screen printing machinery in China.

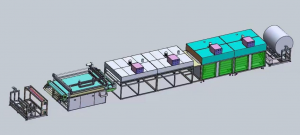

screen printing machine

Aiming at the diversity of market demand, the flexibility and universality of screen printing methods, we continue to develop, improve and upgrade products to meet market requirements in an all-round way. Now we have screen printing machinery and auxiliary equipment of different grades and different application fields.

The main product types are:

Semi-automatic and automatic planar screen printing equipment; screen making, exposure and auxiliary equipment; ultraviolet (UV) drying equipment; infrared (IR) drying equipment; concurrently engaged in various screen printing auxiliary equipment and special screen printing inks.

REHOW screen printing machine is a machine that uses a screen printing plate to print, and it is a kind of printing machine. A screen printing machine is a machine for printing text and pictures, and is a general term for machines or equipment used to produce printed matter. The screen printing machine belongs to the more representative printing equipment in the stencil printing machine. In addition to silk, the material for making the screen can also be nylon wire, copper wire, steel wire or stainless steel wire. It can be divided into flat screen printing machine, curved screen printing machine, rotary screen printing machine and so on.

Screen printing can be divided into many types according to its format, type of printing machine, ink properties and types of substrates, but it can be divided into the following types in terms of printing methods.

1. Flat screen screen printing: flat screen screen printing machine is a method of printing on a flat substrate with a flat screen plate. When printing, the printing plate is fixed and the scraping plate moves.

2. Flat screen curved surface screen printing: Flat screen curved surface screen printing is a method of printing a flat screen printing plate on curved surface substrates (such as balls, cylinders, cylinders, etc.). During printing, the squeegee is fixed, the printing plate moves horizontally, and the substrate rotates with the printing plate.

3. Rotary screen printing: Rotary screen printing is a cylindrical screen printing method in which a fixed squeegee is installed in the cylinder, and the cylindrical printing plate and the substrate are simultaneously moved at the same linear speed.

4. Direct screen printing: In the first three methods, the printing plate directly prints the substrate, but only some regular geometric shapes, such as plane, cylindrical surface, conical surface, etc., are used for complex shapes, corners and depressions. Surfaces and other special-shaped objects must be printed by direct screen printing. The process usually consists of two parts: flat screen printing and transfer printing, that is, the screen printing picture is not directly printed on the substrate, but printed first. On the flat material, it is transferred to the substrate by a certain method.

One of the methods of direct printing is to first print the pattern on the flat glass with the flat screen printing method, and then use the elastic silicone head to absorb the ink pattern from the glass plate like a stamp, and then transfer it to the special shape. Surface: Another method of direct screen printing is decal transfer printing, such as: screen printing decal + thermal transfer, screen printing decal + pressure-sensitive transfer, screen printing decal + solvent activation print. Direct screen printing has become a major field in the printing industry

Post time: May-19-2023