Product Details Product Parameters

The introduction of deep-view textile surface defect detection has automated the transformation of the assembly line, making the textile production line a fast, real-time, accurate, and efficient assembly line. Can greatly improve production efficiency and production automation. The automatic detection equipment for textile defects based on machine vision technology integrates machinery, electronics, optics, computer, and software engineering. It uses machine vision detection equipment instead of human eyes to complete monitoring, measurement and judgment. It is non-contact, repeatable, reliable and high-precision. , continuity, high efficiency, good flexibility and many other application advantages

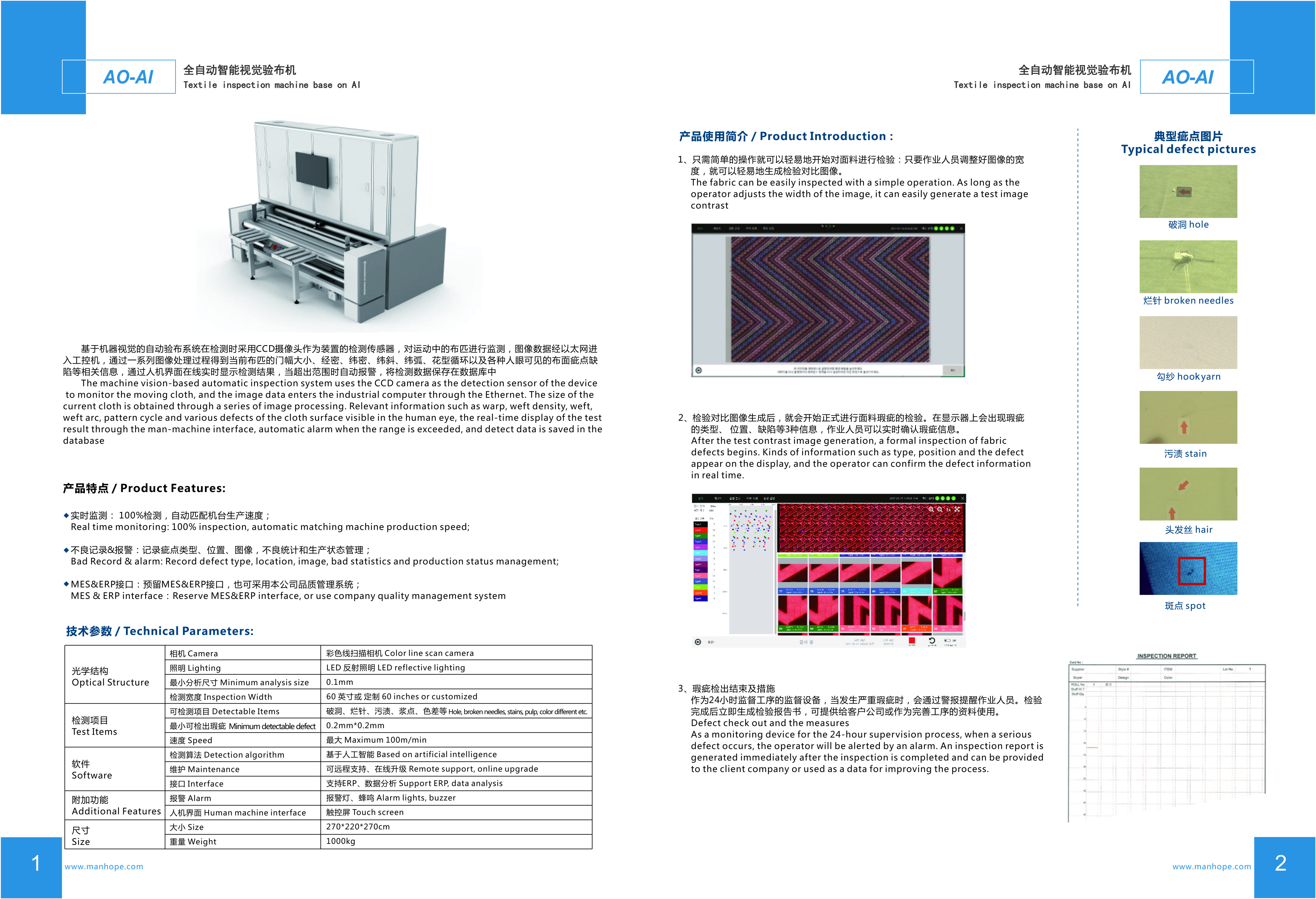

REHOW’s AO-AI intelligent cloth inspection machine is an automatic detection machine for fabric defects such as woven fabrics, non-woven fabrics, and leather, which liberates labor costs and improves production efficiency. Using machine vision detection technology, using a new generation of CCD industrial cameras to simulate human eyes to detect fabric defects; through image capture, parameter analysis, and data comparison, accurately locate the detected fabric defect points; through manipulator/paste Labeling machine etc. mark the defect points, and at the same time produce a detailed inspection report of the cloth.

The intelligent cloth inspection system adopts the following exclusive technologies to ensure efficient detection of material surface defects:

• Using full-spectrum lighting and sensing technology, R/G/B/NIR wide-spectrum detection at the same time, compared with traditional black and white cameras, the detection ability is greatly improved;

• Using FPGA image hardware acceleration defect detection technology, compared with traditional PC software processing, built-in dedicated complex detection algorithm, more stable and efficient;

• Adopt automatic edge-seeking function, which can detect the edge defects of the fabric;

• Using morphological feature analysis technology, it can analyze the defect area, length, width and roundness in real time;

• The real-time automatic correction technology of mechanical shake image error can avoid the influence of mechanical shake;

Compared with manual cloth inspection, REHOW intelligent cloth inspection system has the following characteristics:

• The detection speed can reach 60~250m/min. The manual rate is generally 15~35m/min, and the defects that can be seen by the naked eye will become less and less if it exceeds 35m/min.

• The detection width is generally 1.2m~3.6m, and can also be adjusted according to customer needs. A single manual detection generally does not exceed 1.6m.

• The detection accuracy is generally above 0.1mm. It is basically invisible to the naked eye at a speed of 15m/min.

• The equipment can run continuously for 24 hours, and the detection efficiency is reliable. Manual is prone to visual fatigue, and the detection efficiency is greatly reduced.

• The equipment can accurately and visually record the details and distribution of defects. Manual records are not detailed enough and accurate and not intuitive.

• The equipment can be automatically connected and imported with the customer’s ERP/SAP/MES system, which is convenient for the data and information management of the enterprise.

• The equipment can monitor the weaving process in real time, and if serious defects are found, an alarm can be set to stop the machine, so as to realize online management of product quality, reduce large-scale degradation caused by delays in subsequent processes, and minimize losses.

• Equipment detects most fabric defects:

Weaving defects: broken warp, broken weft, tape yarn, thick places, flying flowers, loose warp, cotton balls, dense roads, thin roads, abrasions, colored fiber weaving, holes, etc.

Stains: oil stains, cloth stains, rust stains, water stains, material stains, oil warp, oil weft, etc.

System operation is simple

1) Alarm and shutdown:

● Immediate alarm: each defect detected by the system can be prompted in the form of sound and light flashing;

● Immediate shutdown: Each defect detected by the system can output a signal to the inspection machine for shutdown.

2) Display content:

●Real-time display of defects, marking the type, location and other information of defects (special text can be marked according to user requirements);

● With playback function, it is convenient for historical viewing;

3) Distribution map:

● Dynamically display defect range and distinguish types with different colors.

● The distribution map can be zoomed in and out to reflect partial or overall information;

4) Record:

●Record the relevant information of the current defect through the data table (production batch number, defect location, coordinates, generation time and other information);

● Immediate deletion of defect records, and manual judgment and modification of defect categories;

● Can directly print reports and defect pictures;

5) Query:

● View historical records through picture wall and data table. And there is a simple chart display position in the data table.

● Multiple query methods: query by batch, time, product name, etc. alone or in combination

Post time: May-08-2023