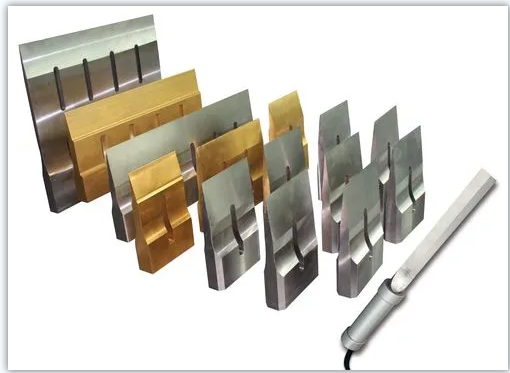

REHOW Ultrasonic Cutting Knife uses high-frequency vibrating blades to cut materials. Specialty textiles and some hard resins, plastics, circuit boards, and 3D printed objects can be cut easily. It can also be used with the grinding rod for grinding operations. Since the high vibration frequency will generate high temperature, the blade should not stay on the workpiece for too long, otherwise the workpiece may be melted.

REHOW produces ultrasonic cutting cutters that can cut: various textile fabrics, curtain fabrics, non-woven fabrics, special materials, industrial textiles, natural fiber segmentation, synthetic fiber deep digging, plastic shell processing, artificial resin paint, hand-held cutting, etc.

Through the action of ultrasonic waves, the grinding wheel blades produce instantaneous telescopic vibrations in the radial direction, so that the abrasive grains and the workpiece can repeatedly collide with each other under high acceleration in a short period of time. As a result, the surface of the workpiece is processed while producing minute cracked layers, so the processing load on the grinding wheel blade can be greatly reduced. In addition, due to the vibration of ultrasonic waves, there is a gap between the grinding wheel blade and the workpiece, which greatly improves the cooling effect of the abrasive grains, and by preventing the occurrence of abrasive grain passivation and pore clogging, the processing of the workpiece can be improved. quality and prolong the service life of the grinding wheel blades.

.

Features of REHOW Ultrasonic Cutter:

1. High stability: When the ultrasonic generator is working, it generates 40KHz electromagnetic vibration, which is converted into mechanical vibration and transmitted to the cutting knife and the material to be cut, and the mechanical cutting is performed, so no sharp cutting edge is required, and the blade wears less , At the same time, the cutter head can be replaced by itself.

2. No pollution: When the ultrasonic knife cuts, the temperature of the knife head is lower than 50°C, and there will be no smoke and odor, which eliminates the danger of injury and fire during cutting.

3. Simple operation: the cutter is connected to the ultrasonic generator, the generator is connected to the 220V mains, and the cutting can be performed by turning on the switch. It supports hand-held cutting and is equipped with an air-cooled interface.

4. Wide range of applications: All kinds of textile materials and plastic sheets can be cut by ultrasonic waves, such as natural fibers, synthetic fibers, non-woven fabrics and knitted fabrics can be cut by ultrasonic waves.

5. Neat cutting: Since the ultrasonic wave cuts through high-frequency vibration, the material will not adhere to the surface of the blade, and only a small pressure is required during cutting. It will not deform or wear fragile and soft materials, and the fabric will be automatically edged while cutting , will not cause edge collapse.

Post time: May-09-2023