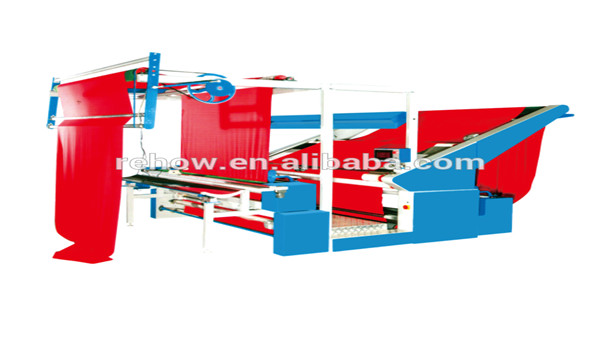

REHOW, a professional manufacturer of cloth inspecting machine, will solve eight common faults of cloth inspecting machine for you. Because of these different faults, we provide the following simple repair methods, which you can try.

Fault 1. When traveling on the cloth inspection machine, the fabric is skewed and “occluded”:

This is mainly because the fabric guide rollers of the fabric inspection machine are not parallel, and the equipment operator can solve this problem by adjusting the parallelism of the fabric guide rollers.

Fault 2. The rollers are not aligned: because the rollers and the guide rollers are not parallel, the rollers are not neat. Therefore, the parallelism between the rollers and the guide rollers can completely eliminate the problem of roller irregularities.

Fault 3. The cloth and heavy cloth of the cloth inspection machine are heavy: it may be caused by dust, cloth and oil in the transmission part or non-transmission part of the machine. Install the fabric inspection machine for transmission. parts and regularly clean the oil and cloth in the machine.

Fault 3. The cloth and heavy cloth of the cloth inspection machine are heavy: it may be caused by dust, cloth and oil in the transmission part or non-transmission part of the machine. Install the fabric inspection machine for transmission. parts and regularly clean the oil and cloth in the machine.

Fault 4. Machine noise: The problem of high machine noise is mainly caused by poor machine lubrication, worn parts or loose screws, and corresponding wear of the drive shaft. This is the correct skew due to the large left and right clearance of the machine. side. We are able to take care of this by timing lubricating equipment, installing each part correctly, and correcting or replacing damaged or substandard parts.

Fault 5. The guide wheel of the cloth inspection machine or each revolution of the guide wheel will produce some hysteresis:

This phenomenon is mainly caused by the poor match between the replacement bearing and the original parts, and the damage and bending of the guide roller and winding roller shaft. It can be adjusted by adjusting the poorly assembled equipment components and then correcting them. The bending deflection of the shaft. deal with.

Fault 6. The brightness of the viewing table glass is insufficient: the lighting brightness of the viewing table glass is insufficient, because the dust on the fluorescent tube and the viewing table glass is too large, so the voltage on the viewing table glass is too high. Rag or unstable bulb. This was easily resolved by frequently removing fluorescent tubes and debris from the glass on the viewing table and stabilizing the lighting voltage.

Fault 7. The counting length of the multi-code equipment is incorrect: In the process of conveying the fabric, the friction force is lacking, and the long-term use of the long wheel or the operation is blocked may cause the fault. Causes the viewer of the cloth inspection machine to be incorrect. The friction friction of the fabric can be increased by increasing the relative temperature of the fabric, changing the length of the gauge wheel, and cleaning the dust and oil on the long wheel frequently.

Fault 8. Other operational faults: Failure to add lubricating oil for a long time will cause other operational faults during the operation of the equipment. These problems can be avoided by simply periodically lubricating the device.

REHOW has an efficient and professional service team, committed to providing customers with high-quality consultation and after-sales service.

Rehow, a professional manufacturer of fabric inspection machines, always adheres to the business philosophy of “integrity, quality, innovation, and win-win” to create a better future hand in hand with customers.

rehow provides textile industry machines to the whole world, helping them improve efficiency and reduce labor costs. REHOW provides various types of textile machinery: Raising machine, cloth inspection machine, packaging machine, half folding machine, half folding machine, winding machine, slitting machine, cross cutting machine, ribbon weaving machine, loom, etc. If you are interested in us, please contact us now!

Post time: May-06-2023