According to the type of fabric, REHOW cloth inspecting and rolling machine manufacturers are very particular about the tension adjustment of the cloth inspecting machine. For knitted fabrics and they are very elastic, effective tension control must be carried out when inspecting and rolling. Generally, the machine is equipped with magnetic powder to control the tension. The effect of magnetic powder on the tension control is not very good. It is feasible to test the rolled woven fabric, but the real application to the knitted fabric with great elasticity cannot be achieved. .

So what should we do? Here I tell you a secret. Check the rolled knitted fabric, because of its high elasticity, it will produce tension under tension. The tension will cause the shrinkage of the fabric width, and the width shrinkage will affect the quality of the fabric, and it will wrinkle. It directly seriously affects the carrying out of the next process, and what is more serious is that it will cause scrapping of the cloth. resulting in great losses. Therefore, for this kind of fabric, it is necessary to choose a fabric inspection machine without tension to achieve no shrinkage and wrinkle-free rolling.

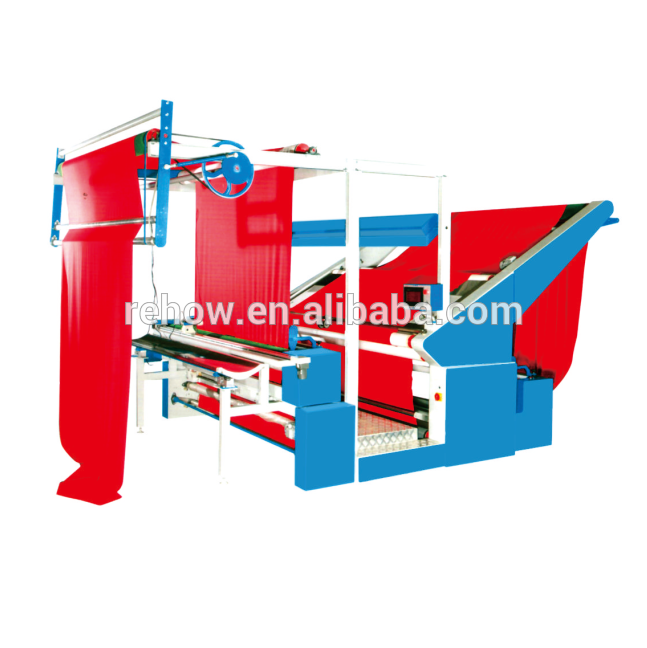

How does the tension-free cloth inspection machine achieve the tension-free effect? In fact, it is also very simple, that is, it is controlled by double frequency conversion and double motors. Use the differential speed between the cloth feeding roller and the cloth winding roller to adjust the tightness to complete the tension-free winding. When the fabric is rolled, look under the cloth inspection light box, touch it with your hand, and you will feel whether the tension of the fabric is high or low. If the tension is high, adjust the elastic knob to loosen it. Rotate in a tight direction, so these must be summed up in the actual production process.

Post time: Apr-23-2023