With the use of new looms, the requirements for the winding mechanism are getting higher and higher, and the traditional winding mechanism can no longer meet the requirements of high-speed new looms and diversified production varieties, so a new type of cloth winding device has emerged. The cloth rolling device outside the loom is a cloth rolling device independent of the loom. The device first leads the fabric out of the loom through the cloth guide roller, and then rolls the fabric outside the loom to shape. The largest cloth roll that can be wound is The fabric is not restricted by the internal space of the loom, and the continuous length of the wound fabric theoretically only depends on the length of the warp yarn wound by the warp beam. The fabric often uses an off-machine rolling device. In recent years, my country has intensified research and development efforts in the manufacture of rapier, air-jet and other loom devices, and the overall technical level has developed rapidly. However, in terms of rolling cloth outside the machine, there are currently very few domestic R&D and production manufacturers, and traditional rolling cloth The device can no longer meet the quality requirements of weaving thick and heavy fabrics, and there are problems such as short replacement of fabric rolls, affecting weaving efficiency and not tight fabric winding. For this reason, REHOW Textile Machinery Co., Ltd. has developed the large roll cloth rolling device outside the machine.

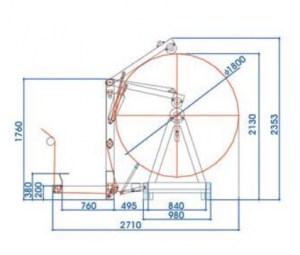

图1 :Large roll cloth rolling machine outside the machine

The structure of the device is simple

Precise tension control

The structure size of the large roll cloth rolling device outside the machine is large and the speed is slow, so we choose the friction wheel drive as the transmission mode. The large cloth rolling device adopts a double take-up roller structure. The cloth take-up roller is placed between the two take-up rollers, and the two take-up rollers rely on friction to drive the cloth take-up roller to rotate to realize the cloth take-up function. Set the number of sprocket teeth on one take-up roller to be 2 teeth less than the number of sprocket teeth on the other take-up roller, so that there will be a speed difference between the two take-up rollers, that is, the take-up speed of the previous take-up roller The winding speed of the latter take-up roller is a little faster, so that the holding point of the cloth surface has a constant and small tension, which can not only prevent the cloth surface from wrinkling, but also make the rolled cloth more tightly.

This device adopts the servo motor of model 92BL (3) D120-30H (ST) as the power, the servo motor is connected with a gear reducer, and the speed of the servo motor is controlled by the electronic control system, so as to realize the adjustment of the cloth winding speed. The optimal operating speed range of the servo motor is 60~3000 rpm.

The fabric winding device outside the machine must strictly control the tension of the rolled fabric during the process of winding the fabric. There are two reasons for this: first, different fabrics require different stretching ratios, and Different stretch ratios must be achieved through different fabric tensions; second, in order to ensure the winding quality of the fabric, the fabric tension must be kept constant or according to a certain law (such as the fabric tension varies with the diameter of the roll cloth) during the entire winding process. increasing and gradually decreasing) changes. If the fabric tension is too high, it will cause the internal grid of the fabric to increase or the fabric will be damaged due to the warp stress; The tension sensing device can detect the tension situation at any time. The principle of tension control is: the tension roller is fixed on the swing support, and the swing support and the swing arm are fastened by screws to form a complete tension sensing arm. The position of the fixed seat changes the force of the tension spring to adjust the swing range of the sensing back beam, thereby adjusting the tension of the cloth, and the displacement sensor sends a signal to the electronic control system to control the tension by detecting the distance from the swing arm.

图2:Schematic diagram of large rolls outside the machine

The cloth roll is just a smooth hollow shaft at the beginning of the cloth roll. In order to avoid slipping of the cloth roll due to insufficient friction and to make the cloth roll more tightly, a pressure roller can be added to the cloth roll. The sprocket is driven by a three-phase asynchronous motor. It is connected with the drive shaft through a coupling and drives the sprocket on the other side. The sprocket on the left and right sides and the chain pass through the fixed ring to place the pressure roller on the bracket and move up and down with the chain. Move (same principle for left and right sides). There is a hook on the transmission shaft, and the pressure roller can be hung on the hook when the cloth is lowered, which is convenient for operation. In addition, the column not only supports the pressurizing mechanism, but also restrains and guides the cloth roll in the lateral direction. The cloth is rolled between the two columns to ensure that the rolled cloth is neat and beautiful. In addition, the independent large cloth rolling device is generally equipped with foot pedals, and the fabric is unloaded through the foot pedals, so it does not affect the operation of the loom by the operator.

Fast dynamic response

good forming quality

The performance of the REHOW external winding device mainly depends on the control accuracy of the fabric tension during the fabric winding process. At present, most of the domestic large roll cloth rolling devices adopt mechanical drive mode or the control mode combining geared motor and frequency converter, the control precision of fabric tension is low, and the forming quality of cloth roll is poor. The large cloth rolling device adopts electric control, and the tension detection adopts displacement tension sensor. In the detection system, the sensor and the machine are closely combined to detect the actual tension value, and the fabric tension control accuracy is high. In addition, the cloth winding device outside the machine mainly achieves the purpose of tension control by adjusting the motor speed, so the speed regulation performance of the motor is a very critical factor. In the past, the cloth winding device outside the machine mostly used the combination of magnetic powder clutch and brake to directly control the tension. However, due to the serious wear and tear of the magnetic powder clutch itself, the accuracy is low, which affects the winding effect; while the DC motor is used, and because its motor The brushes are easy to wear and age, and the control accuracy is not high, which affects the quality of fabric winding. In order to avoid these disadvantages, the device adopts servo control technology, which can not only simplify the structure of the cloth winding device outside the machine, but also make winding easier, and the dynamic response is faster. At the same time, the tension control of the winding device outside the machine can be well controlled Following the characteristics, the fabric tension can be controlled more precisely, so that the fabric roll forming quality is good.

The development of large-volume rolling device for industrial cloth and other heavy fabrics has added a new variety to my country’s textile machinery and filled the gap in domestic similar products. The performance indicators of the above-mentioned self-developed rapier loom outer large package roll device have met the design and use requirements, and can meet the technical characteristics of weaving high-grade fabrics or heavy fabrics such as towels, industrial fabrics, canvas and denim. and usage requirements.

Post time: May-16-2023