The pleating machine is a process of using a certain pressure to shape the fabric into a series of pointed or round pleats under certain temperature and humidity conditions. The main components of the folding machine are pleat mold, push pleat mechanism, heating components, cooling and setting system, control system, etc.

With the popularization of the production and manufacture of textile and garment fabric products, manufacturers have a higher role in the folding machine. Next, the REHOW (rehow) manufacturer will briefly introduce the advantages of the pleating machine in the production of clothing or fabrics.

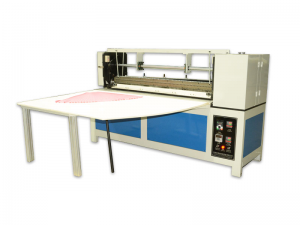

As a kind of textile machinery, the pleating machine is suitable for the pleating process of clothes. The pleated products have beautiful appearance and relatively high work efficiency. The equipment is mainly used for pressing and folding the hem of household items such as bedspreads, tablecloths, and curtains, and for simultaneously discounting decorative seams such as children’s clothing, fashion fronts, and women’s clothing.

After the fabric is wrinkled, the length of the fabric in the wrinkle direction is obviously shortened, and it has good elasticity and stretchability. The production process of fabric wrinkles is relatively complicated. First, design the wrinkled pleats, and then use the pleating machine to carry out high-temperature wrinkling and shaping of the fabric according to the design requirements. There are manual, machine, and manual and machine methods in the production. The production process of fabric wrinkles is relatively complicated. First, design the wrinkled pleats, and then use the pleating machine to carry out high-temperature wrinkling and shaping of the fabric according to the design requirements. There are manual, machine, and manual and machine methods in the production.

After the fabric is wrinkled, the length of the fabric in the wrinkle direction is obviously shortened, and it has good elasticity and stretchability. High-temperature setting is the basis for large-scale production of wrinkled fabrics, which can produce regular and irregular wrinkles. In order to express special wrinkling effects, the pleating machine can first sew the wrinkles according to the design requirements, and then use high-temperature and high-pressure setting to make the fabric More artistic and casual.

clothing discount machine

Jiangsu Suzhou Rehow Machinery Co., Ltd. focuses on the production of ultrasonic equipment, which integrates research, design, production, marketing and service. It has a strong technical force, and constantly introduces domestic and foreign technologies, with reliable product quality and stable system. The company adopts imported raw materials and component supporting products, and has formed fabric folding machines, slitting machines, embossing machines, ultrasonic lace machines, ultrasonic slitting machines, ultrasonic composite machines, slitting and cross-cutting machines, towel slicing machines, and rag slicing machines. Machines and other ultrasonic series products. Integrity management, excellent equipment, the company has a complete and scientific quality management system, welcome new and old customers to consult and cooperate

Post time: May-17-2023