The paddle shaft is a device for stirring, mixing and conveying slurry, which is often used in chemical, pharmaceutical, food processing and other fields. The following is an introduction to several common parameters in the design:

1. Diameter: Diameter refers to the cross-sectional diameter of the product, which is generally determined according to the required stirring power and the viscosity of the liquid. The larger the diameter, the higher the rigidity and strength of the product, which can withstand greater stirring force.

2. Length: Length refers to the distance from one end of the shaft to the other. The choice of length should take into account the depth of the container and the requirements of the stirring work. Longer products can cover a larger stirring area, but also increase the cost of materials and the complexity of installation.

3. Material: Corrosion-resistant and wear-resistant materials are usually used, such as stainless steel, carbon steel, etc. The choice of material depends on the nature of the liquid being processed and the requirements of the working environment.

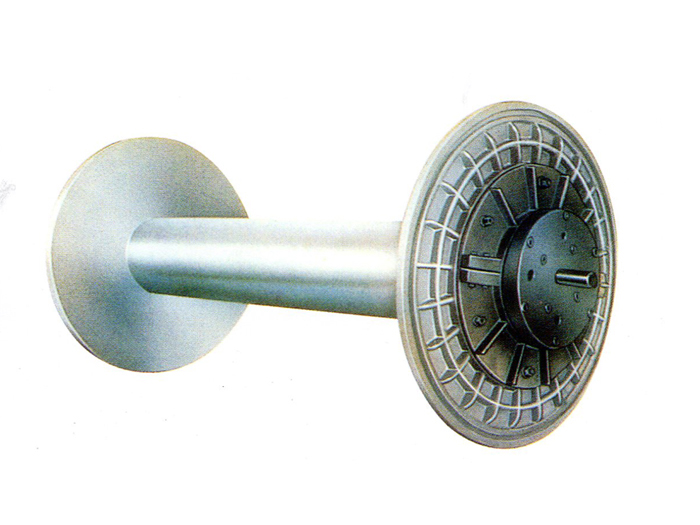

4. Stirring blade: The stirring blade is a rotating part fixed on the paddle shaft, which is used to stir the liquid. The type and shape of the mixing blades are selected according to specific application requirements, such as paddle blades, propulsion blades, spiral blades, etc.

5. Axial gap: The axial gap is the distance between the product and the bottom of the container, which affects the stirring effect and the circulation of the liquid. A small axial clearance can improve stirring efficiency, but ensure enough space to avoid friction and seizure.

6. Rotation speed: Rotation speed is the rate at which the product rotates, usually expressed in revolutions per minute (RPM). The choice of rotation speed depends on the needs of mixing, including factors such as mixing uniformity, bubble generation and shear force.

REHOW Textile Machinery

An enterprise specializing in textile machinery manufacturing, it is committed to providing high-quality mechanical equipment and technical solutions for the global textile industry.

The product range of Jiangsu REHOW Textile Machinery covers almost all types of fabrics, including but not limited to hank machines, looms, loom machines, warping cars, cloth cutting machines, electric warping cars, warping warehouses, slitting and slitting machines , Rolling machine, ultrasonic slitting machine, opening width machine, cloth inspection machine, warp beam. REHOW Textile Machinery continues to lead the textile industry with its innovative approach and rich experience. We welcome offers and partnership opportunities with open arms!

The above are some common parameters in the design of the propeller shaft. The actual design needs to be comprehensively considered according to the specific application requirements, process parameters and vessel structure, and optimized and adjusted according to experience and experimental results.

Post time: Jun-03-2023