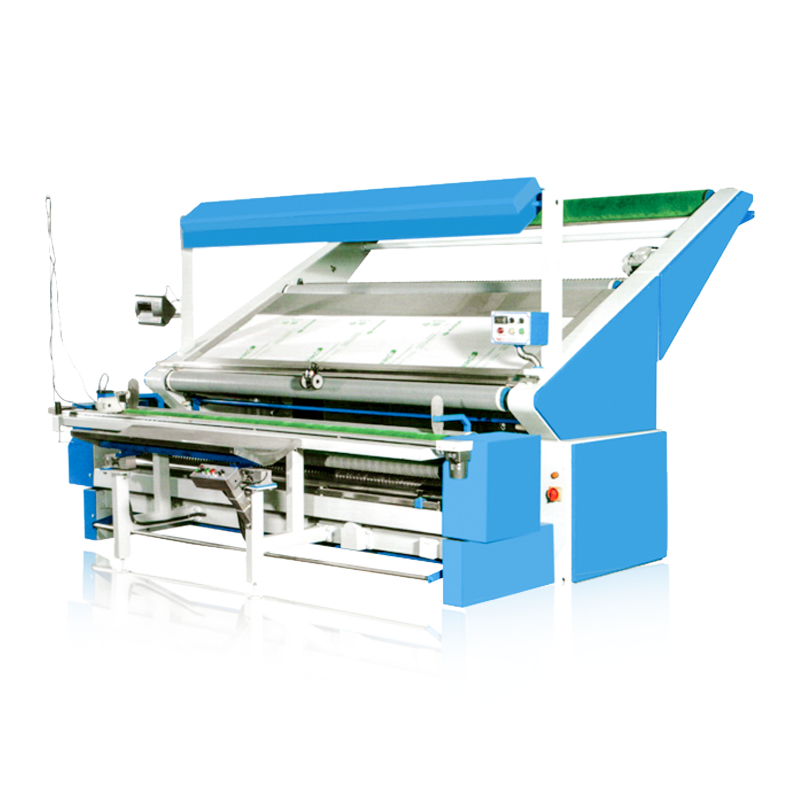

OW series knitted fabric inspecting machine is a set of necessary special equipment for inspecting cotton, wool, linen, silk, chemical fiber, etc. in large format, double-width and single-width before production in the garment industry. The working method of knitted cloth inspecting machine : Provide a hardware environment for cloth inspection, continuously unfold the fabric in sections, provide sufficient light sources, and the operator can detect surface defects and color differences by visual observation, and the knitted fabric inspection machine automatically completes the length recording and package finishing work. The cloth inspection machine with good performance is equipped with an electronic defect detection device, which is statistically analyzed by a computer to assist in the cloth inspection operation and print out.

The basic structure of knitted fabric inspection machine includes:

1) fabric unwinding, dragging and rewinding device;

2) Cloth inspection table, light source and lighting;

3) coding device;

4) fabric finishing device;

5) Starting, reversing and braking devices. Traditional manual cloth inspection workers can find up to 200 defects within 1 hour, and the concentration of manual inspection can last for 20-30 minutes at most. Over this time, cloth inspection will cause fatigue, and the inspection speed is only 5-20 m/min. Exceeding this speed will result in missed inspections.

The knitting cloth inspection machine can replace manual work, automatically inspect and grade the cloth, cut it, and label the defects. The knitted fabric inspection machine relies on the reflection of the light source and the light guiding effect to inspect the cloth. The normal inspection speed can reach 120m/min. It works by the terminal control system, and the detected defects can be displayed on the screen. , fast and easy, can adapt to high-frequency defects or new defects that rarely occur, and has a memory function, which can calculate and process more defects. The knitted fabric inspection machine can be used to classify fabrics and carry out the function of statistical memory storage of the defects of the inspected fabrics. The knitted fabric inspection machine makes the inspection of fabrics move towards automation. It is believed that after a certain period of continuous efforts in research, Cloth inspection machine technology will enter textile enterprises and form one of the important links of automation.

Post time: Dec-05-2022