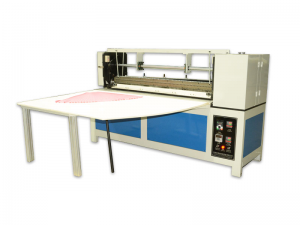

Before clothing is made, we need to conceive and process the fabric, and the pleating machine is used at this time. We use the pleating machine to process the fabric. So how to use the pleating machine produced by rehow textile machinery correctly, and how to carry out the improvement and upgrading activities of the pleating machine? Now I will give you a brief introduction, hoping to be helpful to your use.

During the folding process, the angle, extrusion force and extrusion time of the folding blades are mostly determined by a rigid device cam, which controls the movement of the blades and exerts force between the blades. Such a cam system is designed to adapt to the general regulation of the inclination angle of the general or standard filter media pleating blade, the extruding duration and the variation range of the extruding force. For media that are highly sensitive to device strain, such as microfiberglass, membrane media, polycarbonate or fiberglass-bonded webs, standard blade motions often do not achieve the required quality standards.

The pleating machine adopts the forced oil return device at the needle bar to effectively control the measurement of the needle bar structure and eliminate the phenomenon of oil leakage. Upper and lower silicone oil equipment to avoid needle heating and thread breakage. The single-needle pleating machine is a kind of pleating machine, which can sew two-color rope stitches with similar braids and the same shape composed of two colors on ordinary fabrics. The stitching is beautiful and generous, and its size and thickness can be adjusted to a large scale, which has a good embellishment effect.

1. In the pleating machine, the automatic pleat height detection and control at its discharge tray. According to the acceptable stamina limit for each filtered product. This error rate is automatically matched to the detected pleat height. If the acceptable error rate is exceeded, as long as the operator selects this option in the preset pleating program, an automatic alarm will start or the machine will automatically stop;

2. The fully electronic pleating machine brings all computer-controlled parameters for permanent detection, and additionally brings manual adjustment parameters, such as the back pressure value of the back pressure from the top pressure cylinder;

3. Produce shorter pleated bottoms or shorter pleated top types. Shorter pleats can be conceived as center pleats alternating with standard pleats or as short pressed pleats marked by the edge of the filter. Even a way of folding pleats with 3 or more different pleat sizes in one continuous process can be conceived.

To sum up, we understand the main points of using the pleating machine, the angle and extrusion force of the pleating blade are very critical, sometimes the force is not well controlled, and accidents are likely to occur

Post time: May-17-2023