From the end of each year to the end of March of the next year, it is the equipment procurement period for clothing, bags, car decoration and other industries, that is, the traditional sewing machinery market sales peak season. With the increasingly fierce market competition and the continuous improvement of market demand, laser equipment such as laser cutting machines for clothing fabrics have been widely used.

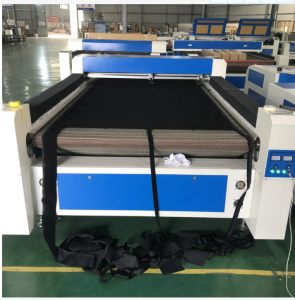

图:Fabric Laser Cutting Machine

How to choose a suitable laser cutting machine? Choosing a suitable fabric laser cutting machine generally depends on the production material. Generally speaking, the following issues need to be considered:

1. Fine cutting seam: the laser cutting seam is generally 0.10mm-0.20mm;

2. The cutting surface is smooth: the cutting surface of laser cutting has no burrs;

3. Small thermal deformation: the laser slit in laser processing is thin, fast, and energy concentrated, so the heat transferred to the material to be cut is small, and the deformation of the material is also very small;

4. It is very suitable for the development of new products and shortens the research and development cycle: once the product drawing is formed, laser processing can be carried out immediately, and you can get the real product of the new product in the shortest time;

5. Saving materials: Laser processing adopts computer programming, which can cut products of different shapes and maximize the utilization rate of materials.

Rehow’s laser slitting cutting machine is a kind of equipment for trimming and slitting wide-width materials according to different needs in the production process. Among them, the fabric slitting machine is mainly used to cut wide-width coils into various narrow-width coils suitable for production needs. The slitting process includes two processes of unwinding and winding. The tension control of the unwinding material and the winding material is the key link of the slitting machine. The fabric slitting machine is based on the original electronic control system, which adds automatic edge control, which achieves the ideal effect, improves the working performance of the machine, makes the machine more stable in high-speed operation, and the winding is smooth, and the operation is simple and convenient. , safe, reliable and durable.

Laser slitting machine features:

1. It is welded by thick steel plate to be firm and balanced in angle, so that the machine can work stably at high speed

2. The whole machine is made of chrome-plated steel pipe, each of which has been dynamically balanced

3. The unwinding adopts a 3-inch air-expanding unwinding shaft, and the maximum unwinding diameter can reach 600mm. It is equipped with a magnetic powder tension controller and an automatic edge alignment device.

4. Rewinding adopts 3-inch air-inflatable reel and magnetic powder tension controller for rewinding. The slitting operation is simple, and the maximum rewinding diameter can reach 600mm; the rewinding is beautiful and tidy.

5. The cutting knife can use industrial surgical blade or flat knife (art blade), adjustable knife between 18mm-1600mm

6. The spindle and the circular knife use a stepless speed change system, which can be used as high and low speed regulation and forward and reverse switching control; the electronic speed regulation system can manually adjust the speed of the machine during use, which is convenient and simple

7. Equipped with double-sided diamond grinding and sharpening system, the life of the grinding wheel can reach up to two years; the knife can be sharpened without disassembly, so that the blade can be kept sharp for a long time; to achieve the best cutting quality; and track cleaning

图2:Garment Laser Cutting Machine

8. REHOW laser slitting cutting machine adopts imported precision ball screw and slide rail to advance the cutting width in parallel, and the imported AC motor adjustment system can steplessly adjust and control the cutting speed, so as to achieve high-precision cutting, and the accuracy can be controlled within 0.1mm

9. Equipped with a high-precision deviation correction device system to further ensure cutting accuracy

10. Chinese and English operation interface, LCD display screen, can directly input several kinds of cutting width and quantity settings, and has manual/automatic conversion function, making the operation easier and more convenient

11, rehow laser slitting cutting machine adopts fast feeding design, loading and unloading can be completed with only one action, which effectively reduces the labor in production and thus improves production efficiency.

12. Automatic counting device, clear at a glance.

Post time: May-16-2023