AI intelligent cloth inspection machine is characterized by high efficiency and high benefit

An intelligent cloth inspection machine can replace 2-5 traditional cloth inspectors, which can save enterprises millions to tens of millions of expenses every year.

Average speed of manual cloth inspection: 13m/min

Average detection speed of intelligent cloth inspection machine: 30m/min

Take 90 yards of plain weave fabric as an example: when the speed of the intelligent cloth inspection machine is 30m/min, the cloth inspection speed is 3 minutes/piece, and the number of cloths to be inspected in one hour is 8 pieces, about 700 yards, and 6000- 7000 yards of cloth.

High recognition rate, low compensation rate

Stable, accurate and efficient identification. It saves the cloth inspection by naked eyes in the early stage and the film inspection by naked eyes in the later stage, greatly reduces the missed inspection rate of defects, and reduces the customer compensation problems caused by missed inspections and wrong inspections. Improve corporate image, solve inspection problems through equipment, and improve quality control.

Artificial average detection rate: 70%

The average detection rate of intelligent cloth inspection machine: more than 90%

Recognition accuracy: 0.1mm (decrease over time)

Recognition accuracy: 0.01mm (long-term stability)

Low labor dependence, continuous production capacity and stability

24-hour uninterrupted automatic detection, the working cycle is up to 10 years. The staff training time is short, which effectively solves the problem of production capacity fluctuations caused by difficult recruitment, personnel turnover, human eye fatigue, and holidays.

digitization, informatization

Open interface, fast docking with ERP, MES and other production management systems, and textile automation such as automatic cutting machine, automatic spreading machine, automatic packaging machine, etc.

The equipment is connected in series to form a textile intelligent production line to create a textile digital intelligent factory.

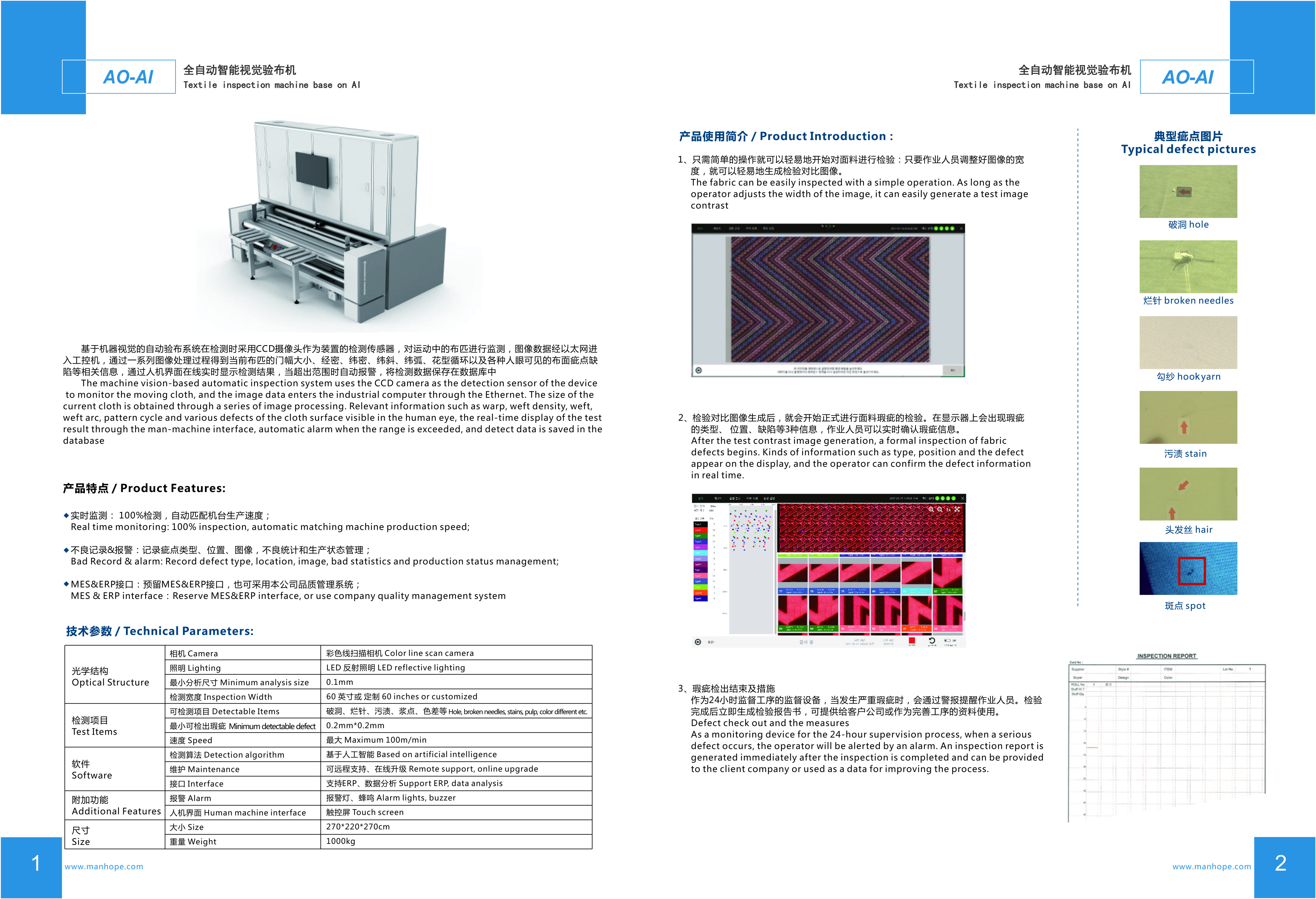

Fabric defects, types, and industry informatization, real-time detection pages, and real-time viewing of fabric inspection conditions.

other features

①Visible defect map, standard American four-point scoring system, real-time output of professional fabric inspection report.

② Adaptive light source intensity:

③Single point test:

④ Auxiliary judgment of defects:

⑤ Defect marking method::

⑥Imported electrical control module, high-precision powered and non-powered rollers.

REHOW will provide a complete system, including software system, industrial computer, printer, in order to guide customers to use our system, we have prepared instruction videos in our youtube.

REHOW Textile Machinery specializes in high-end intelligent textile machinery manufacturing enterprises, has an efficient and professional team, is committed to providing customers with high-quality consulting and after-sales service, and is committed to providing high-quality mechanical equipment and technical solutions for the global textile industry.

It mainly produces high-speed looms, cloth inspection machines, cloth packaging machines, slitting and slitting machines, cloth coding machines, cloth rolling machines and other textile equipment. We have independent research and development capabilities and a complete quality management system. All products have undergone strict quality testing and certification to ensure product stability and reliability.

Post time: May-04-2023