1. First of all, understand the steps of measuring weft inclination when inspecting woven fabrics:

In the vertical state of the cloth surface, first find a balance line as a reference, align one end with that line, and then measure the height/(low) of the other side to get the height of the balance line, so as to be higher/(lower) ) divided by the width of the door width, is the number of weft skew. Search Jushang Meiyu to read the full text. Tear off a piece by hand, then align the selvedge and fold it in half, see the difference of up to a few centimeters and divide it by the width of the door to get the percentage. It’s hard to say, it depends on the style. If there are stripes, it is more troublesome. It is basically no problem if it is below 5%. When the discharge exceeds this limit, the left and right bone positions should be considered to be inclined in the same direction to avoid twisting the cylinder.

2. Control of weft skew:

According to the type of weft skew, different weft adjusters can be used. The principle of weft adjustment is to adjust the relative running speed between the warp yarns of the fabric through the mechanical action of the overall mechanism, so that the corresponding part of the weft yarn skew is “advanced” or “lag”, so that Restore the state where the weft and warp intersect perpendicularly across the entire width.

3. Reasons for weft skew

Why is the weave of the fabric and the fabric fibers of the knitted fabric in a slanted state? Or a snake-like twist in the fabric weave? This phenomenon, known as weft, has two causes.

Reason 1: If the fabric design or knitted fabric design is poor, it will form a weft skew state. In this case, the design itself had to be completely changed.

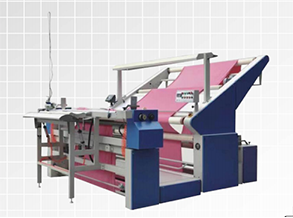

Reason 2: Although textiles are made according to normal weaving and design, weft skew is formed during the dyeing process and printing process. This weft skew accident mostly occurs in the plain weave of short fiber fabrics and filament fabrics in dyeing and printing factories. The reason is that weft skewing tends to occur in rope-like dyed and washed cloth. Because the softer the fabric, the easier it is to deform. Therefore, if the rope is dyed and dyed with a dyeing machine similar to this, the weft skew of the plain weave is particularly significant, and it is easy to form the weft skew and snake (S shape) state of the fabric.

When bending produces defective products and the texture of the fabric is bent, all textiles (dip dyeing, continuous dyeing, printing) using the fabric will become defective. Especially when printing and finishing, the bending state is clear at a glance. Printing and finishing using a weft-slanted fabric results in a state of “bending” accidents. The printed pattern is curved to the fabric. If the squeegee guide belt of the rotary screen printing machine or the automatic flat screen printing machine sticks to the fabric that has not been wefted, it will easily cause weft skew.

4. Solutions to weft skew

(1) Comparing the dimensions of the latitude in the above two pictures, it is not difficult to see that the degree of latitude in the latter has been significantly improved. In order to solve this problem, the cloth passes through the oblique rod of the cloth before the adjuster, and a tension difference is formed on the left and right sides of the cloth to correct it. In addition, there are many factories that place adjusters while correcting the weft skew and snaking of the cloth by hand. However, this method cannot completely eliminate weft skew. There are many factories like this.

REHOW Textile Machinery is a company specializing in textile machinery manufacturing, and is committed to providing high-quality mechanical equipment and technical solutions for the global textile industry.

complete solution

(2) When using the adjuster to correct the weft skew and snaking state of the cloth through human visual inspection and manual operation, if there is a mistake in the visual inspection and manual operation, there is a danger of the weft skew or snaking of the cloth in an instant. The way to completely prevent weft skew is to install a weft skew correction device (weft trimmer) in front of the adjuster or in front of the printing machine. If the cloth passes through this device, weft skew can be eliminated. If use sensor and microprocessor and specially designed guiding device these three interlinked appropriate devices (weft adjusting device), it is possible to correct weft skew in unmanned way.

Post time: May-15-2023