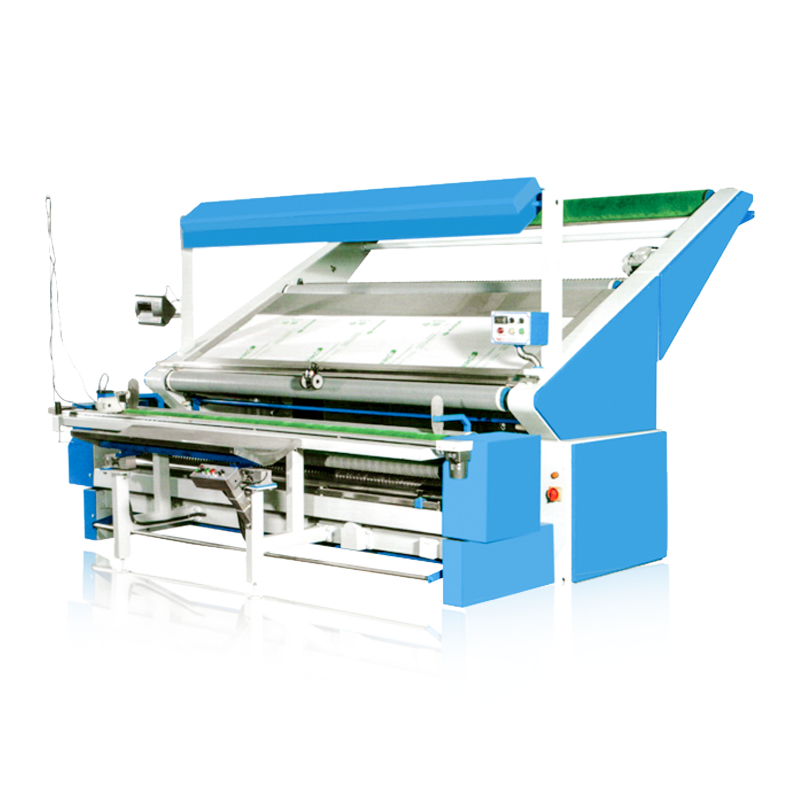

The fabric inspection machine is specially used for the inspection of various fabrics before mass production to prevent inferior fabrics from flowing into the production line, so as to ensure the quality of garment fabrics.

The operator must have the ability to check the point, line and surface of various fabric defects.

Cloth inspection machine operation essentials:

1. Put the inspection cloth in the middle of the machine.

2. Close the air switch.

3. Roll the cloth around the plastic tube for 3-5 turns first, then set the opposite side switch to the “ON” position, and lift the plastic tube slightly so that the opposite side device can track to the edge of the cloth.

4. Put down the plastic tube after it is in place and stop tracking, rotate the upper rear roller of Jinlong Machinery to fully tighten the cloth, and move the baffles on both sides to resist the plastic tube.

5. Press the “forward rotation” button, the machine will start to work, its speed is controlled by the speed potentiometer, the right rotation speed is super fast, and the left rotation is vice versa

Fabric inspection machine attention

1. If you want to change the steering direction of the cloth inspection machine, you must wait until the motor is completely stationary before pressing the reverse button, otherwise the motor will be overloaded and burned.

2. When the motor is stationary, do not turn the adjustment handle to avoid damage to the machine.

3. When the cloth is sent off, please record the counter value and turn off the side switch of the cloth inspection machine in time.

Post time: Dec-13-2022