Cylindrical knitted fabric air-flow turning machine is one of the fabric finishing machines. It mainly uses the principle of wind to turn the reverse side of the simple knitted fabric for dyeing and finishing, and then turn it back after dyeing to avoid fabric in the dyeing and finishing process. received pollution.

The existing air-flow turning machine usually puts the cylindrical knitted fabric on the outside of the cloth turning cylinder directly. Rubbing against the top of the fabric turning cylinder may cause damage to the knitted fabric. In addition, the knitted fabric is directly placed outside the fabric turning cylinder. During the fabric turning process, when the airflow blows the knitted fabric to move, the moving speed of the knitted fabric may be uneven, affecting The effect of cloth turning. In addition, after the cloth turning process of some existing devices, the turned gray cloths are piled up in scattered piles, requiring staff to sort them out, which is time-consuming and laborious. The distance is usually fixed, and the airflow speed can only be adjusted through the fan inside the rack. Frequent adjustment of the fan may cause damage to the fan.

Technical realization elements:

Aiming at the deficiencies of the existing technology, REHOW Company invented and provided an air-flow turning machine for circular knitted fabrics, which has the advantages of ensuring uniform movement of knitted fabrics, free adjustment of air velocity, and collection of processed fabrics, etc., which solves the above background Questions raised in technology.

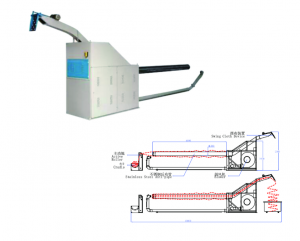

In order to achieve the above objectives of ensuring uniform movement of knitted fabrics, free adjustment of airflow speed, and collection of processed fabrics, the present invention achieves the following technical solutions: an airflow turning machine for circular knitted fabrics, including a support table, the The left side of the top of the support table is fixedly equipped with a frame main body, and a cloth turning cylinder is fixedly installed above the right side of the frame main body, and uniformly distributed auxiliary pulleys are fixedly installed on the outside and inside of the top of the cloth turning cylinder. The lower part of the right side of the main body of the rack is fixedly installed with a first-level air duct, and the top of the first-level air duct is movably socketed with a second-level air duct. A drive screw is sleeved, the top of the support table is fixedly installed with a support plate that is movably connected with the drive screw, and the side of the support plate is fixedly equipped with a first drive motor whose output shaft is fixedly connected with the drive screw. The top of the main body is fixedly installed with two vertical plates located on the front and rear sides of the cloth turning cylinder, and the sides of the two vertical plates are movably socketed with adjustment rods, and the top of the adjustment rods is fixed with an auxiliary splint, and the auxiliary splint Auxiliary pulleys evenly distributed are fixedly installed on the inner surface, and a second guide rod penetrating to the outside of the vertical plate is fixedly installed on the outside of the auxiliary splint, and a compression spring is movably sleeved on the outside of the second guide rod, and the top of the main body of the frame A fixed plate is fixedly installed on the left side of the fixed plate, and a gearbox is fixedly installed on the side of the fixed plate, a second drive motor is fixedly installed on the side of the gearbox, a rotating shaft is movably installed on the side of the fixed plate, and the External fixed installation with fixed splints.

Features and parameters of tubular knitted fabric air turning machine:

1. Technical features:

1. It is suitable for turning fabrics before dyeing and washing of tubular knitted gray fabrics;

2. Stainless steel cloth turning pipe, double pipe design, air flow direction control for cloth loading and unloading;

3. High-speed feeding, large feeding volume design, high efficiency.

4. There is no damage and pinch marks during the cloth unloading process, and the cloth runs smoothly at a high speed.

5. Foot control, more simple and convenient operation.

6. Optional parts: Cloth loading device, easy to operate.

2. Technical parameters:

1. Working type: Air-flow turning

2. The maximum loading capacity: 200kg

3. Maximum turning speed: 80m/min

4. Dimensions of turning cloth tube: Φ250×L4800mm

5. Motor power: 7.5kW + 0.2kW

6. Dimensions: 7420×1150×2560mm

Post time: May-13-2023