Aiming at the low level of automation of domestic open-width machines, a method based on CCD identification and calibration of missing stitches and PID control is proposed.

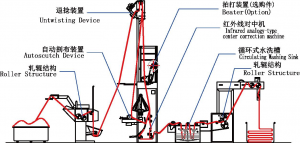

VS-E Untwisting, Scouring and Squeezing Machine

VS-E Untwisting, Scouring and Squeezing Machine

Automatic visual alignment method for umbrella frame motor. The image of the fabric is taken by a CCD camera, and the computer recognizes and locates the missing stitches. according to

The offset direction and size of the missing stitch and the cloth cutting knife are adjusted by the PID controller to adjust the rotation direction and speed of the umbrella frame, and the deviation between the missing stitch and the cloth cutting knife is corrected.

amount to ensure that the fabric is divided along the drop stitch. Matlab simulation shows that the system can detect missing stitches in real time and control the rotation speed of the umbrella stand, and the response

The response speed is fast, the detection accuracy is high, the reliability is good, and a good control effect has been achieved.

Due to the excellent fabric adaptability and production efficiency of the circular weft machine

For flat knitting machines, circular weft knitting machines occupy a large proportion in modern textile applications. but

The cylindrical fabrics produced by most circular weft machines need to be opened and shaped before they can be

For printing and dyeing, therefore, a leak stitch with a width of about 1nlnl is preset during the knitting process, and the cloth splitting knife cuts the fabric along the leak stitch when opening the width. At present, most of the tracking and identification of missing stitches on open-width machines in China adopts manual adjustment. The operator needs to pay attention to the position of the missing stitches at all times. stitch with

Cutting knife aligned . This manual adjustment method is inefficient and labor intensive.

Due to the importance of the textile industry to the national economy and the domestic open-width machine

In view of the status quo with a low degree of automation, research on automatic open-width machines has broad development potential.

development prospects and huge economic value.

At present, many manufacturers at home and abroad are committed to the research and development of

Automatic open width machine. Such as the many developed by China REHOW Textile Machinery Company

Functional rope fabric open-width machine, which can cut semi-finished cotton fabric or fiber at the same time

The dimensional fabric completes the 4 processes of dehydration, untwisting, opening and rolling.

High functional integration. Domestic open-width machine research started relatively late, and the product

Less dynamic. But in recent years, China’s automatic control of open-width machines

The system research has made great progress, and the developed fabric leak stitch tracker mostly uses a photoelectric sensor to detect the difference in light intensity between the leak stitch and other positions of the fabric, so as to locate the leak stitch. Jiangsu rehow company and others have developed an infrared photoelectric tracker suitable for a variety of fabrics, using a single-chip microcomputer to control the stepping motor, which greatly improves the opening speed and accuracy.

Realized the photoelectric detection of judging the position of missing stitches according to the output of the sensor

array tracker. Jiangsu rehow company adopts software computing generation

Replace the four arithmetic operations in traditional circuits to deal with PSD (Position Sensitive Detection

device, positionsensitivedetector) signal, improve the accuracy of the system

speed and stability.

In view of the fact that the combination of visual inspection and automatic control technology has not yet been

Applicable to the automation research of open-width machines, REHOW Machinery Company proposed a method based on

Automatic visual alignment of CCD identification and calibration of missing stitches and PID control motor

The line opening method, the experiment proves that the automatic vision line opening system can realize

Real-time detection of fabric missing stitches and control the rotation speed of the umbrella frame to ensure missing stitches

The alignment of the seam and the cloth cutting knife realizes the automatic processing of the open-width machine.

1 Principle of VS-E Automatic Vision Alignment Open Width Machine

First of all, in the image acquisition subsystem, the CCD camera is responsible for fast,

Accurately collect the fabric passing through the umbrella stand, and transmit the image to the industrial computer for identification. Then, in the image recognition subsystem, through image preprocessing

Eliminate the influence of the environment on the original image, use image processing technology to identify, mark

Identify the position of the needle seam and calculate its deviation from the slitting knife. at last ,

The umbrella stand control subsystem receives the deviation of the image recognition subsystem, and presses

According to the deviation of missing stitches, the rotation speed of the umbrella stand and the control of the rotation of the umbrella stand

The change law between the speed of the stepper motor is controlled by the PID controller

Stepper motor to adjust the rotation speed of the umbrella frame, so as to ensure the missing stitch and cut

The cloth knife is aligned.

2 CCD-based recognition of missing stitches in fabrics

Since the CCD has non-contact, fast measurement speed, high precision, and

Reliability and other advantages, so this system uses CCD to realize fabric leak stitching

identification.

2.1 Design of CCD fabric drop stitch centering device

A part of the open-width machine used to fix or support the centering device, cutting cloth

The knife is fixed on the open-width machine, which is aligned with the initial position of the missing stitch; CCD

The camera is placed above the slitting knife and the fabric, and the CCD camera is required to match the position of the fabric.

Vertical in the plane, and ensure that the cloth knife and the fabric are in the field of view of the CCD camera

Center, so that the CCD camera can always capture the position of the missing stitch and the cloth knife

place. During the working process, the CCD camera transmits the captured fabric image

Go to the industrial computer for identification to calibrate the missing stitches, and calculate the missing stitches and section

The position deviation of cloth knife. When the cutting line exceeds the allowable deviation range, the centering device will automatically send out a signal corresponding to the deviation, and the umbrella stand control subsystem will receive the deviation signal, and control the motor to adjust the rotation speed of the umbrella stand through the PID controller, so that the missing needle seams Gradually return to the ideal center position.

Jiangsu rehow company develops a system based on CCD to identify missing stitches and PID control

The automatic visual line opening method of the motor, the application of image processing technology

Identify missing stitches, calculate its deviation from the cloth cutting knife, and use the PID controller

Adjust the rotation direction and speed of the umbrella frame according to the deviation to ensure that the cloth cutting knife

Automatically divides the fabric along the drop stitch. The experimental results show that the system responds

Fast speed, high detection accuracy and good reliability realize the automatic operation of the open-width machine

change. This paper mainly focuses on the study of monochrome fabrics, and the research on printed fabrics

Missing stitch image recognition method needs to be further improved.

Post time: May-26-2023