The hemming machine is a kind of equipment in textile machinery, which uses a sewing machine to sew the fabric after folding the fabric in half. The feeding and half-folding of the traditional edge sewing machine is done manually, which not only has low production efficiency, but also tends to skip stitches and break needles when the fabric is running at a high speed. Recently, the automatic folding and sewing machine control system based on a complete set of industrial control products designed by PLC, servo driver and frequency converter has been successfully applied to a textile printing and dyeing company. Production efficiency has also been greatly improved.

TSMAutomatic Cylinder Sewing Machine

Technical features of TSM automatic folding and seaming machine:

Technical Features:

1. This high speed sewing machine is suitable for the viscose, the nylon, the polyester fabric

2. Fabric enter by open-width method, maximum width up to 2800mm

3. Equip with four “human sharp” rollers

4. Fabric leading rollers wrapped by PVC, actuated by the digital frequency changer

5. Equip with tension roller, control the fabric tension

6. Equip with 2 sets of central adjustment device, use to adjust the fabric

7. Use smooth stainless steel to manufacture the folding triangle, can be controlled automatically, ensure the fabric to be folded accurately

8. Sewing machine automatic spotting system, actuated by digital frequency changer, helps the operation runs smoothly. Through the special devices, sewing can be as close to the selvedge as possible. This device can work even the selvedge is not leveled, no manpower is needed

9. Germany electronic curling preventing device, equips with 3 chrome fingers, set up in front of the sewing machine, ensure selvedge can be unfolded from inner curl

10. Already sewed fabric release by fabric waver, the tension that exists while sewing can be controlled by over feed method on fabric waver

11. Special high speed sewing machine, single sewing, lubricating automatically

12. Electronic controlling fabric feeding speed synchronize with sewing speed, which can be adjusted easily on the control box

13. A complete set of control buttons are equipped on the control box

14. Breakage alarm-equipment with break off monitor, cloth tail alarm-equipment with break off monitor

15. Low voltage electric circuit board

技术Parameters:

1. Power supply request Approximately 5KW

Compressed air: 5 ATOMs

Diameter: 8MM

2. Work area 2300MM

3. Speed Max. 60 M/MIN

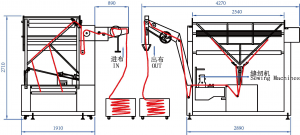

4. Size 5000(L)*3100(W)*3080(H)MM

5. Maximum 30 m/min

speed depends on the type of cloth (Japan imported clothes front)

6. Weight 1300KG

REHOW Textile Machinery Co., Ltd. is a professional company that produces and sells garment machinery equipment. The quality of the garment machinery produced by the company has been well received by customers for a long time. In order to strengthen quality management, improve corporate image, and better meet customer needs, our company has increased management efforts, making our company have new breakthroughs in quality.

At present, with the service tenet of “do not try our best, but try our best”, we attach importance to product quality and service quality, and meet new challenges with a new attitude.

At the same time, I would like to thank all the new and old customers for their consistent concern and support to our company. REHOW Textile Machinery will extend its warm hands and sincerely welcome all new and old customers to come again.

Jiangsu Suzhou Rehow Machinery Co., Ltd. specializes in the production of textile machinery and equipment, which integrates research, design, production, marketing and service. It has a strong technical force, and constantly introduces domestic and foreign technologies, with reliable product quality and stable system. The company adopts imported raw materials and component supporting products. The product range of REHOW textile machinery covers almost all types of fabrics, including but not limited to “computer-automatic” cutting and binding machines; 1. New flat-push computer-automatic cutting and binding machines; 2. New closed infrared ray automatic side-to-side twill rolling machine; 3. Knife sharpening machine; 4. Mechanical positioning strip cutting machine; 5. Automatic side-to-side twill rolling machine; 6. Twill rolling machine; 7. Cross cutting Strap binding machine; 8. Straight knife cutting and binding machine; 9. Automatic edge-to-edge cloth inspection machine; 10. Strap crimping and shaping machine (strip ironing machine); 11. Automatic paper tube cutting machine; 12. Finished product inspection 13. Cloth inspection and falling machine; 14. Simple cloth rolling machine.

We believe that “focusing on what users care about” is the eternal survival point of the enterprise, and customer satisfaction is the unremitting pursuit and struggle of “REHOW”. Customers solve problems and share a win-win situation.

Post time: Jun-03-2023