The concept of the Internet of Things was first proposed by the Massachusetts Institute of Technology in 1999.

pointed out that it relies on radio frequency identification (RFID) technology to realize logistics information

Intelligent management of information systems. The current Internet of Things technology has developed into a

A global network of people and devices that connects anyone with

“Things” with switches connected to the Internet (or connected to each other

connected), through smart sensors, radio frequency identification, GPS and other technologies, to achieve

When collecting any objects or processes that need to be monitored, connected, and interacted, collect

Various needed information, such as sound, light, electricity, heat, location, etc., use various

Different kinds of network access to realize the extensive chain between things and things, things and people

connection, realize the intelligent perception, identification and management of items, and keep them

Optimum status, thereby increasing resource utilization and productivity levels, improving human

relationship with nature. It can be seen that comprehensive perception, reliable transmission and intelligent

The ability to process is the basic feature of the Internet of Things. Information between things and things, people and things

Information interaction is the core of the Internet of Things.

With the new generation of information such as big data, cloud computing and mobile Internet,

With the development of technology, the Internet of Things technology is gradually being realized in manufacturing, retail, transportation

Applications in communications, logistics, medical care, energy, finance and many other fields. along with

The pace of transformation and upgrading of the textile industry continues to accelerate, and the in-depth development of the integration of industrialization and industrialization

The application of Internet of Things technology in the textile industry is becoming more and more extensive. thing

Networking technology through textile equipment and equipment, textile equipment and people, and management

The interconnection of management and execution systems, as well as the perception and transmission of data generated during the period

transmission, processing and application, not only realized in chemical fiber, spinning, weaving, dyeing

Wholesale, clothing, home textiles and other production and manufacturing applications are still in the textile industry

Logistics warehousing, marketing, terminal applications and other aspects to show their talents, become

Enterprises reduce operating costs, improve production efficiency, and then enhance comprehensive competition

important means of power. Combined with examples, this article summarizes the current Internet of Things

The status quo of application and development of technology in the field of textile industry is for readers.

1 Application of Internet of Things Technology in Textile Industry

With the continuous development of technology, the level of informatization in the textile industry is not

Continuous improvement, the process of digitization, networking and intelligence is accelerating, and the

New technologies such as networking, cloud computing, and big data have gradually penetrated into the textile industry.

Production, research and development, management, warehousing, logistics and other links have greatly improved

The operating efficiency and international competitiveness level of the industry. Currently, textile and garment production

The product already has the data acquisition and tracking of the whole production process and the whole life cycle

The basic conditions for tracking analysis, the Internet of Things technology has been widely used in the textile industry

It is widely used in material and product identification, production process and environmental monitoring, production

Quick error correction and remote repair of equipment, logistics tracking and product traceability, etc.

noodle. At the same time, the application of Internet of Things technology in the fields of manufacturing, commerce and trade circulation

It lays the foundation for the tracking and tracing of the whole process of product quality, and establishes a comprehensive

The textile and clothing quality and environmental protection traceability system covering the entire textile industry chain will have

To promote the green development of the textile industry.

1.1 Application of Internet of Things Technology in Chemical Fiber Field

In the field of chemical fiber, the application of Internet of Things technology is mainly reflected in the digital

production and intelligent warehousing. At present, a large number of chemical fiber enterprises are building a whole

The intelligent production workshop of the process, the realization of the chemical fiber automatic logistics and storage system

Intelligentized enterprise logistics. Intelligent vehicles for chemical fiber filaments such as polyester and nylon

Occasionally in the production line, the status information of each controller on the production line is collected through the industrial computer

No., coordinate industrial robots to automatically complete the package drop in the chemical fiber production line

Rolling, bobbin changing, stacking, packaging, transportation, testing and other tasks form a

An integrated solution for chemical fiber filament warehouse management. In addition, information identification

system, computer monitoring system, automatic control system and other digital integrated systems

The application of the system has further improved the standardization, informatization,

The level of automation and intelligence effectively reduces the labor cost of enterprises and improves

High production, operating efficiency and product quality level.

1.2 Application of Internet of Things Technology in Spinning Field

In the field of cotton textiles, a large number of enterprises have passed digital cotton spinning

equipment, automated logistics equipment, online monitoring system for the whole spinning process, etc.

Realized the whole process automation, digital monitoring and intelligent management, the process

The automatic conveying of materials in the room, also appeared in the unattended workshop at night, the equipment

The production process and faults can be remotely controlled and diagnosed.

The level of ingot labor has dropped from an average of about 60 to 10 to 15 people (Figure 1).

Taking the application of online control technology in spinning as an example, through the single spindle of spinning frame

On-line detection and production monitoring technology can realize the spindle speed, machine

Real-time monitoring of vehicle speed, drafting area, ring plate, yarn twist, etc., convenient

It is convenient for managers to understand the operation status of each spindle in the workshop in real time and refer to

treatment, and then optimize the spinning speed curve to ensure the consistency of yarn quality

And stability, reduce the number of parking, improve work efficiency. winder

Sequence, spinning mill through electronic yarn clearing device and winding expert system (such as REHOW

expert system), not only can remove all kinds of yarn defects, but also can

The yarn quality information of each spindle position on the machine realizes the electronic test of online detection

room function.

Spinning workshop data analysis developed by REHOW Machinery Co., Ltd.

The analysis and management E system can realize real-time data of all equipment in the workshop

Collection, online adjustment of process quality, remote control of equipment failure and other management functions

Ability to realize equipment and production information management; workshop environment for research and development

Monitoring system, through temperature and humidity sensors, water wind pressure sensors and remote

Energy measuring instruments, etc., realize the monitoring of workshop air conditioning, dust removal, compressed air, electricity

Integrated control of the power supply system, so as to automatically schedule and manage the production environment of the workshop

environment, which can not only realize energy conservation and emission reduction, green production, but also timely discover and discharge

Eliminate hidden dangers in production; and automated logistics equipment includes AGV can trolley, rough

Fine-link conveying system, fine-link system, automatic stacking machine for bobbin, automatic bobbin

Logistics equipment such as dynamic packaging machines can realize automatic transfer of materials between processes.

delivery. The complete set of digital cotton spinning equipment effectively improves the production of spinning process

efficiency and product quality, reducing the labor intensity and production process of the staff

reduce the energy consumption of the process, improve the working environment of the workshop, and strongly support the textile

The technological upgrading and transformation of the industry.

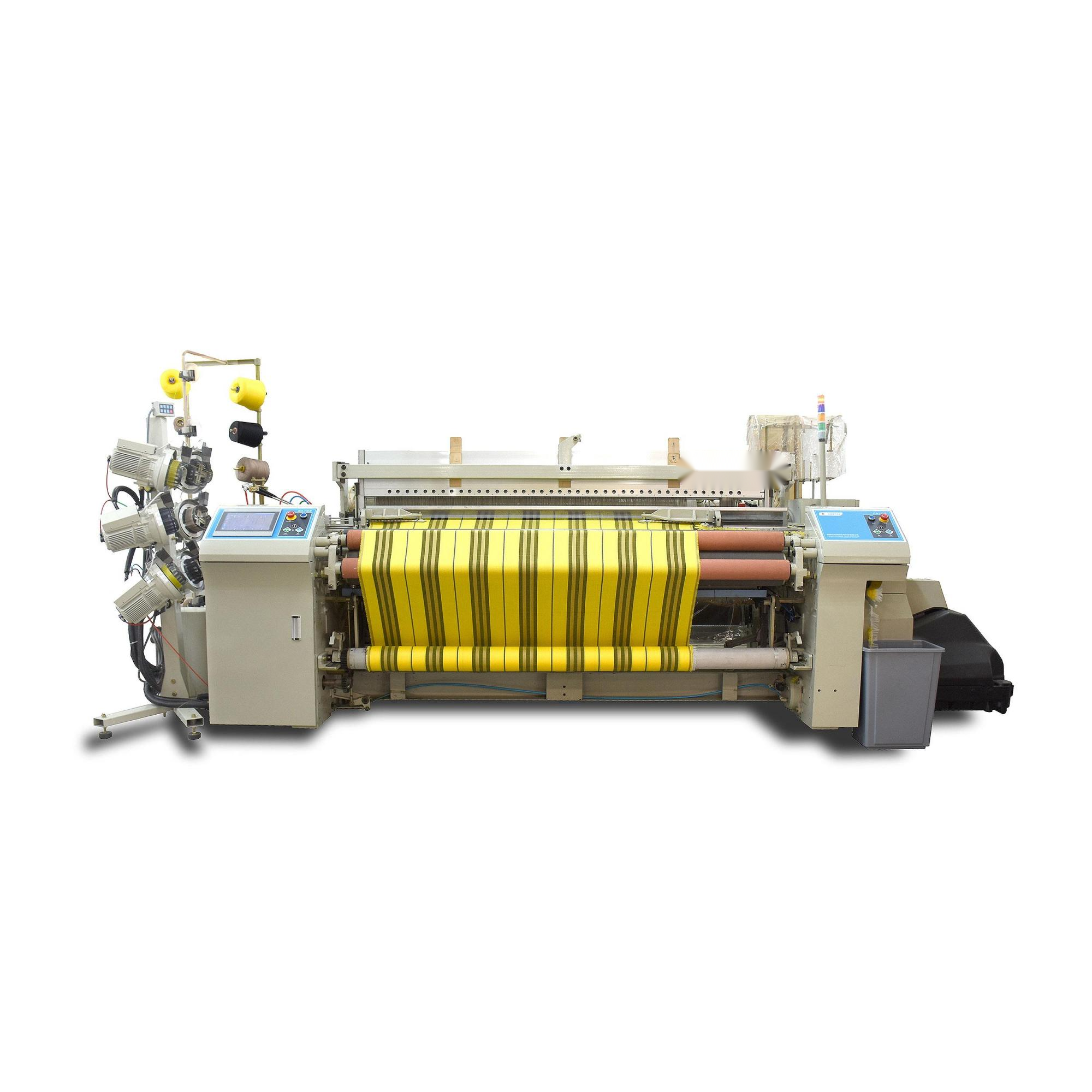

1.3 Application of Internet of Things Technology in Weaving Field

The application of Internet of Things technology in the field of weaving is mainly reflected in the

According to the network, weaving equipment and computer aided process design system, production management

Management system Unicom, through sensor technology to realize equipment status, production data

Online monitoring of data, process data and pattern data, through wireless network

Transmission technology realizes quality inspection and management in fabric production and material

The automation and intelligence of materials, transportation, and warehousing are enhanced by cloud computing technology.

Large data information processing and analysis capabilities realize massive production management for enterprises

Efficient collection, storage, organization, analysis and sharing of management information, further

Improve production methods, reduce production management costs, and improve corporate competitiveness.

During the “Thirteenth Five-Year Plan” period, as the key promotion of 6 intelligent production

One of the line (workshop) construction projects, the construction of intelligent knitting production line will pass

The knitting equipment is connected with the production management system through the data network to realize the

Online monitoring of equipment; integrated computer-aided process design system, yarn detection and defect detection system of machine vision technology, to realize machine grouping

Management and online detection of fabric quality; at the same time construct material warehousing, scheduling,

Intelligent conveying system reduces labor intensity of workers and improves production efficiency.

图1:sewing machine

1.4 Application of Internet of Things technology in the field of dyeing and finishing

In the field of printing and dyeing, the application of Internet of Things technology is mainly reflected in the production line

Digital monitoring, automatic weighing and distribution of dyes and chemicals, and process control systems, etc.

aspect. At present, many enterprises in the Yangtze River Delta and Pearl River Delta have realized

For printing and dyeing processing mechanical parameters, process parameters, energy consumption and process quality

The production monitoring of the whole process, and the integration of the automatic distribution system of dyes and chemicals, form a

The closed-loop control of the complete machine or unit machine ensures the quality of the product in the whole life cycle

Quantity and safety traceability, improve the level of printing and dyeing automation and digitalization, and improve

Production speed and product added value, reducing labor and energy consumption. “Weavers

The “Thirteenth Five-Year” Outline of Scientific and Technological Progress in the Industry pointed out that by 2020, India will achieve

The automation and intelligence of the whole dyeing process, and the Internet of Things technology

Apps will play an important role in this.

In the field of digital online measurement and control of textile printing and dyeing, REHOW textile machinery

Co., Ltd. adopts machine vision-based weft whole technology, whole flower technology and tooling

The intelligent imaging technology of the industrial camera realizes the weft texture and pattern of the fabric

Accurate detection, its correction accuracy can reach 1.0 cm/m width, breaking the traditional

The photoelectric weft trimming machine and the ordinary image weft trimming machine have different effects on fabric weaving, texture, and density.

degree, yarn density and other restrictions, the whole flower function solves the problem of jacquard cloth,

Deformation of patterned fabrics such as printed fabrics and yarn-dyed fabrics, weft adjustment

The function solves the twill, sanding, thin and thick that cannot be solved by photoelectric weft adjustment

The problem of weft alignment of heavy, chiffon and other textiles improves the quality of fabric finishing

The secondary forming rate is improved, the fabric grade is improved, and the production energy consumption is reduced.

REHOW intelligent weft and flower all-in-one machine

图2 Fabric rolling packing machine

1.5 Application of Internet of Things Technology in Clothing and Home Textiles

The production process of clothing and home textiles is relatively long, with high process discreteness and high quality.

There are many types, a large amount of sewing, a lot of labor, and a high degree of labor intensity. smart sensor

The application of device technology and RFID technology in the field of clothing and home textiles will promote the

The intelligent continuous production of clothing and home textile products improves product quality and transforms

Industry development mode and realization of industrial upgrading. Using RFID technology in the field of clothing

For example, the RFID real-time production line in the garment industry uses RFID electronic work tickets

Instead of traditional paper barcode work tickets, it truly realizes the production schedule, employee form

Real-time collection of production data such as present, time required for each process, quality information, etc.

Set, through the real-time monitoring of the workshop, on-site timely scheduling,

Balance the bottleneck of on-site production, improve the production process, and save labor costs at the same time

cost, improve work efficiency, and enhance the ability of enterprises to respond to market changes. this

In addition, RFID technology is widely used in clothing, home textile products, electronic tags, and electronic tag collars.

The application in the field will solve the traditional production workshop management, anti-theft and anti-imitation, production

Sales and other issues, to achieve information monitoring and management, to provide managers at all levels

Decision support information supports rapid business development.

In terms of the application of Internet of Things technology in the field of clothing production, rehow company remotely connects its cutting equipment to the rehow service center, embeds more than 100 sensors into its cutting equipment, and provides real-time monitoring and remote diagnosis through smart devices connected to the call center , predictive services to guarantee uptime, performance, quality

Key performance indicators such as volume; at the same time, upgrade this device-based service to

To use the collected big data to provide consulting services for the cutting room to optimize

Maximize the work efficiency of the entire cutting room and help enterprises achieve operational excellence.

REHOW R&D RFID technology is more competitive. Automation refers to the production management through machines after no one is directly involved, and the expected operations are met through automatic detection, information processing and analysis and judgment.

The application of industrial control automation technology mainly realizes the detection of instruments and meters through control and computer information technology, which can better reduce the corresponding detection means, and meet its output and reduce energy consumption through control and adjustment means. Due to the large-scale application of automation technology in the textile industry, it can change the production energy efficiency of enterprises after technological innovation matures.

Post time: May-16-2023