2021 good selling Chinese textile machinery market status and textile machinery classification

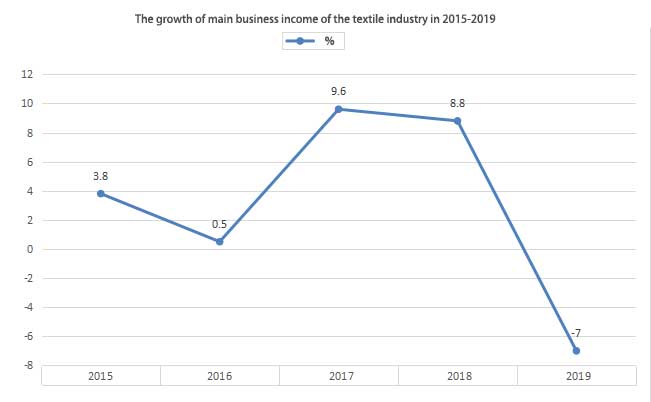

Textile machinery is the foundation for the development of the textile industry. It was first developed in developed industrial areas in Europe. At present, high-end textile machinery manufacturers are mainly concentrated in Germany, Switzerland, Italy, Belgium, Japan and other countries. my country has become the world’s the largest textile machinery manufacturing country. The industry has complete product categories, complete varieties, and convenient supporting facilities. Product output accounts for more than one-third of global output. The gap between overall product performance and advanced products in Europe and Japan has gradually narrowed. Data show that in 2019, 675 textile machinery enterprises above designated size achieved operating income of 81.952 billion yuan, a year-on-year increase of 7%.

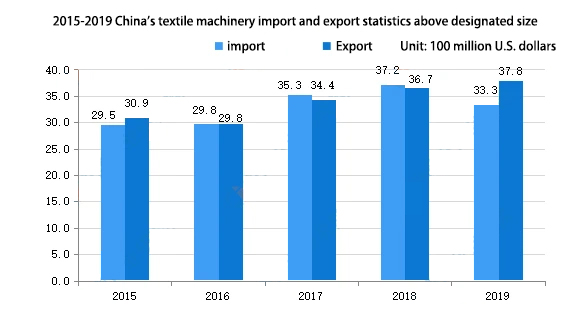

In 2020, my country’s textile machinery industry will be affected by the impact of the new crown epidemic. Data show that in 2019, the import value of textile machinery enterprises above designated size in my country was 3.333 billion U.S. dollars. In 2019, the export value of my country’s textile machinery enterprises above designated size was 3.783 billion U.S. dollars.

Textile machinery classification

The main process flow of weaving is as follows: spinning machinery spins various natural and chemical fibers into yarn, weaving machinery weaves the yarn into cloth, printing and dyeing machinery dyes and finishes the cloth, and finally uses clothing machinery to make the fabric. clothing.

There are many types of textile machinery involved, and textile machinery companies generally can only produce some of them.

1. Spinning machinery

Spinning machinery is a textile machinery that spins various natural fibers (cotton, wool, hemp, silk, etc.) and chemical short fibers into yarns. Among spinning machinery in my country, cotton spinning machinery accounts for more than 60% of the market.

2. Weaving machinery

The weaving process includes weaving preparation, weaving and finishing processes.

A loom is a device that intersects the warp and weft threads arranged perpendicular to each other to form a fabric. In the weaving process, the loom introduces the weft yarn into the opened warp yarn layer (composed of several warp yarns of the same length arranged in parallel), so that the warp and weft are interwoven to form a fabric. This process is called “weft insertion”. The weft insertion method of the loom is divided into shuttle weft insertion and shuttleless weft insertion. Looms are also divided into two categories: shuttle looms and shuttleless looms. The shuttle loom adopts the traditional weft insertion method. The shuttle introduces the weft yarn into the opened warp yarn layer. Shuttles are generally made of wood or composite materials with good impact resistance, wear resistance and toughness, and have a certain degree of elasticity; in the working process of the machine, the shuttle needs to be repeatedly picked to complete the weft insertion; due to the large volume and heavy weight of the shuttle loom , Shuttle looms have high vibration, high noise, slow speed and low efficiency. The shuttleless loom uses small, light-weight weft insertion devices (such as air jets or water jets, rapier heads) instead of shuttle weft insertion; after the shuttleless looms were introduced to the market in the 1950s, they were light in weight, low in vibration and noise. The advantages of low speed, high speed and high weft insertion rate continue to replace shuttle looms. Shuttleless transformation of looms has become a trend in the global loom market. At present, the proportion of shuttleless looms in developed countries has reached more than 90%, while the proportion of shuttleless looms in my country is only about 50%. The market for shuttleless looms in my country is large. Shuttleless looms are divided into rapier looms, air jet looms, water jet looms, projectile looms, etc. according to the different weft insertion carriers.

3. Printing and dyeing machinery

The printing and dyeing process includes pre-printing and dyeing preparation, dyeing, printing and dyeing and post-treatment processes.

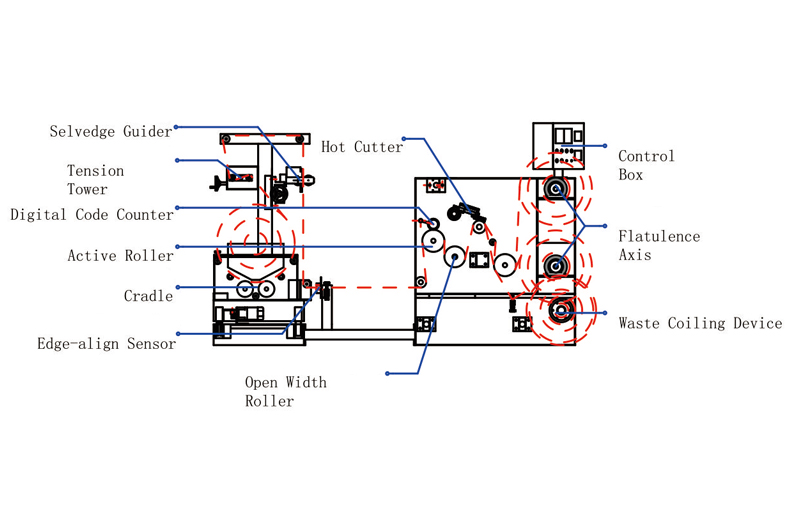

Rehow Machine RH-400A Slitting Machine With Hot Cutter

This machine is widely used in the production area of lace, garment processing, embroidery, banners production, packaging, gift processing, footwear processing, packaging

etc.

Technical Parameters:

| 1. The maximum cutting width | 1800-3200 mm |

| 2. The minimum slitting width | 10 mm |

| 3. Maximum cutting speed | 0-40m/min(depend on the material) |

| 4. Power | 5kw(depend on the amount of cutters) |

| 5. Voltage | 380V |

| 6. Weight | 1500 kg |

| 7. Dimension | 2800mm×2400mm×1600mm |

Post time: Nov-14-2021